Superior Line of Products

Stainless Steel Grooved Fittings

GroovJoint Stainless Steel Grooved Fittings Product Line

GroovJoint Stainless Steel Grooved Pipe Fittings are designed to reduce labor costs in the field by using the grooved method for the installation of piping systems.

GroovJoint grooved pipe fittings are full-flow design in both 304L and 316L grades of stainless steel. conforming to ASTM A403 in sizes 1" - 12".

For product ranging from 1" - 12", fittings are offered in both Sch. 10 and Sch. 40 wall thicknesses. Sch. 40 fittings can be roll grooved or cut grooved depending on the customer’s requirements.

14" - 24" roll grooved fittings are manufactured from material conforming to:

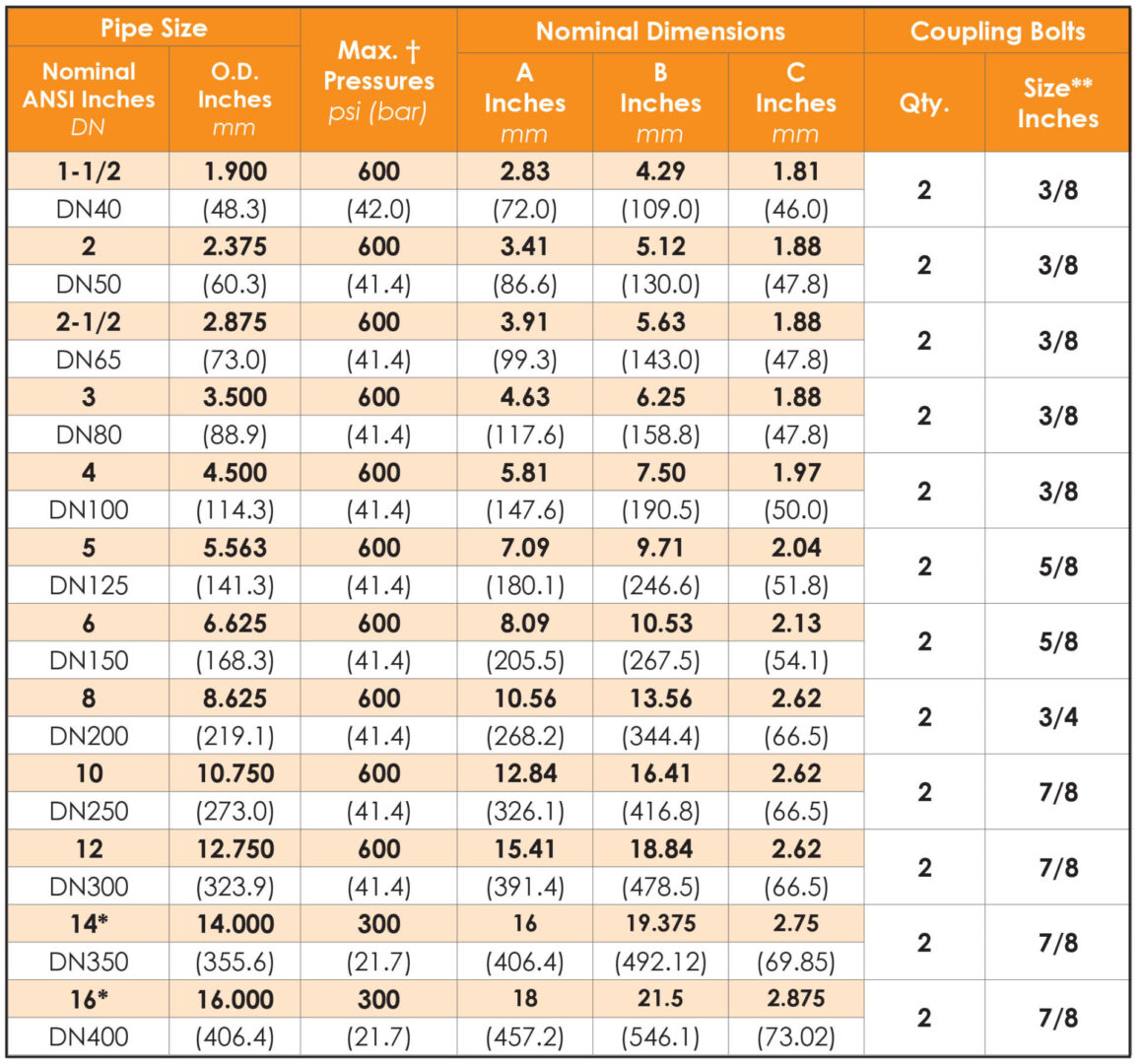

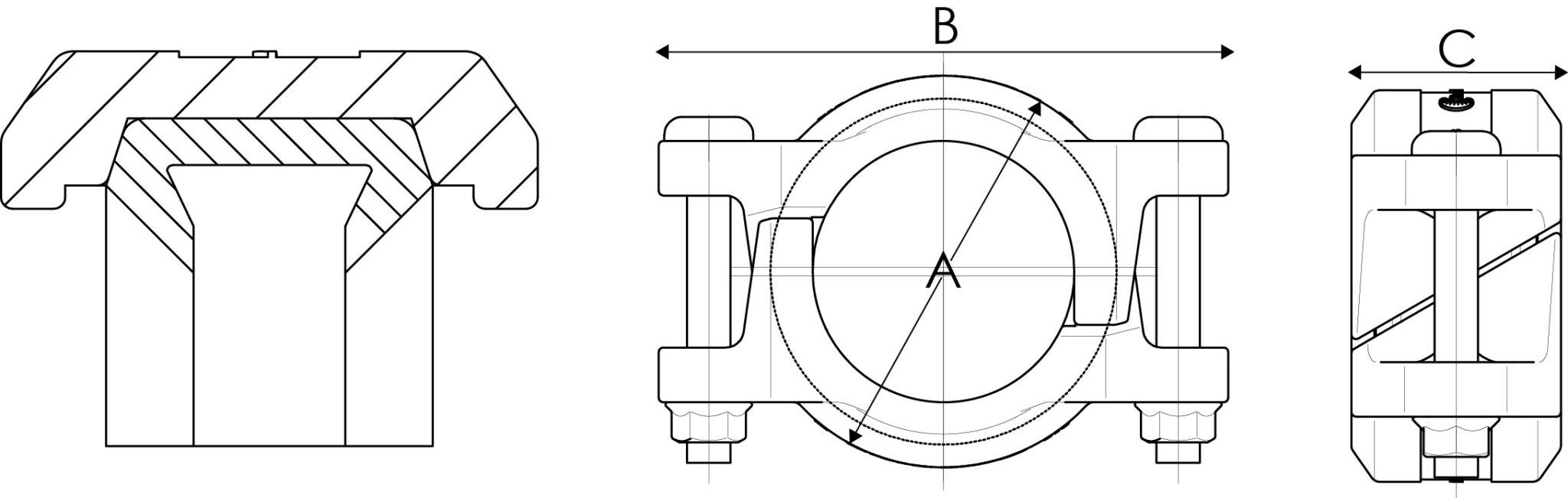

Rigid Couplings

part #24

Standard Weight Rigid Coupling with “C” Gasket

Maximum working pressure depending on schedule of pipe:

1-1/2"–12" Sch.10 stainless steel pipe 300psi (20.7bar)

1-1/2"–12" Sch. 40 stainless steel pipe 600psi (41.1bar)

316 Stainless Steel Couplings conform to ASTM A743/A743M

14" & 16" Couplings: 316 Stainless Steel Body. Offered with either EPDM or Nitrile Buna Gasket. Pressure Rating Maximum is 300 psi.

304 SS Flanged Nuts, 304 SS Bolts. Type 304 Stainless Steel Trac bolts to ASTM A193 B-8 with heavy-duty washer nuts conforming to ASTM A194 B8, Molybdenum disulfide coated.

*NOTE: 14" and 16" Rigid Couplings are not yet UL or NSF approved.

Tested and Certified

to UL 213 Standards

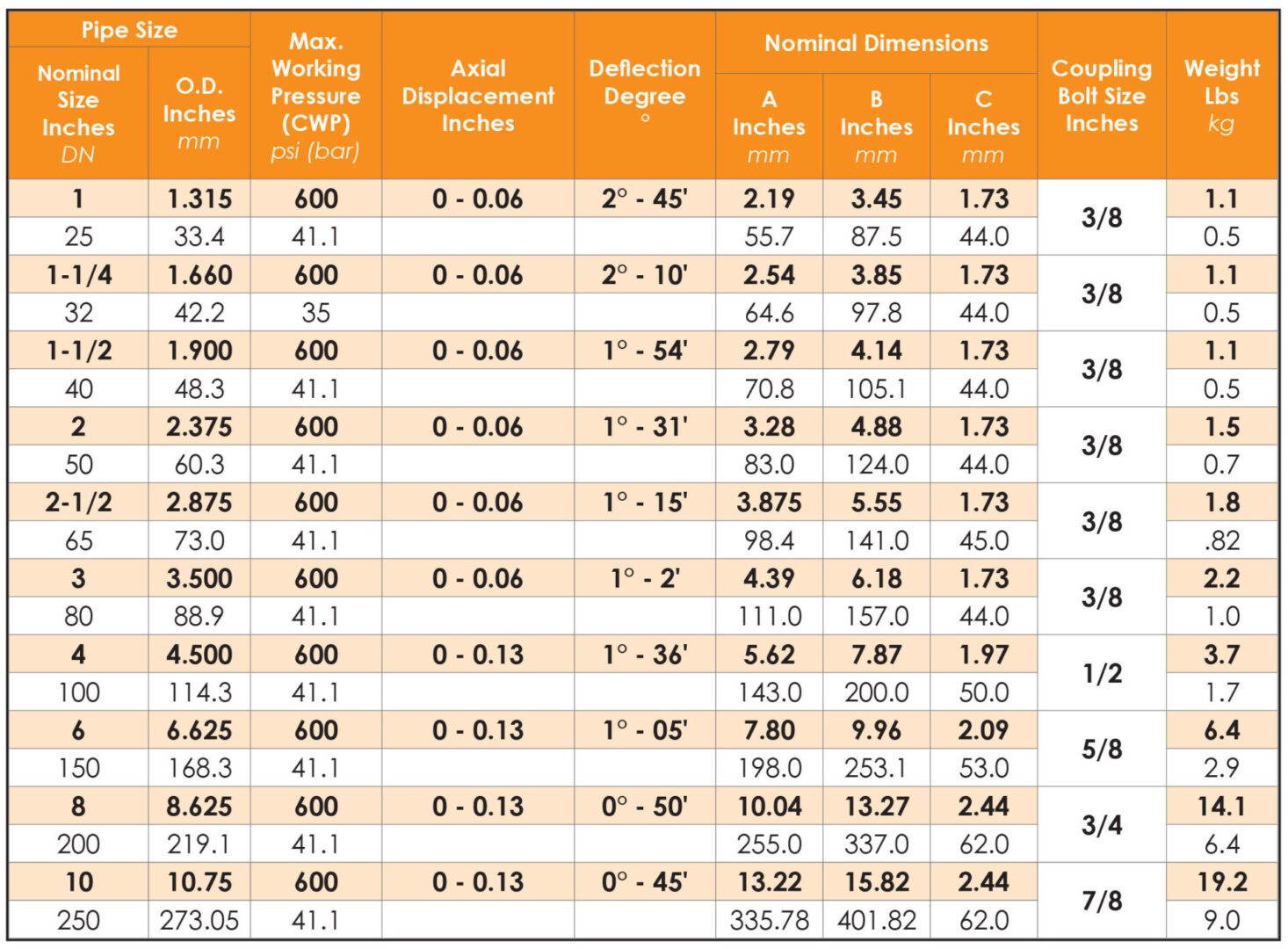

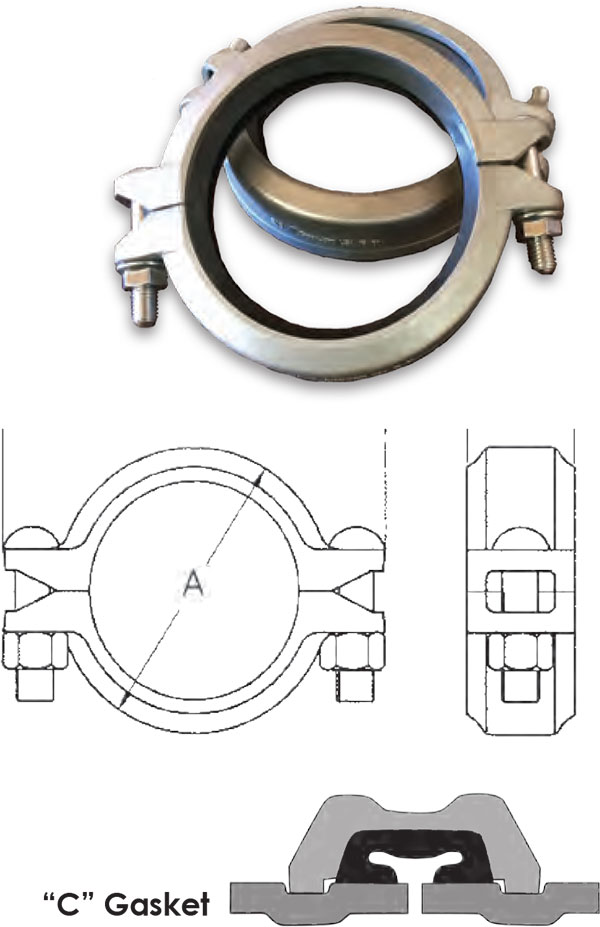

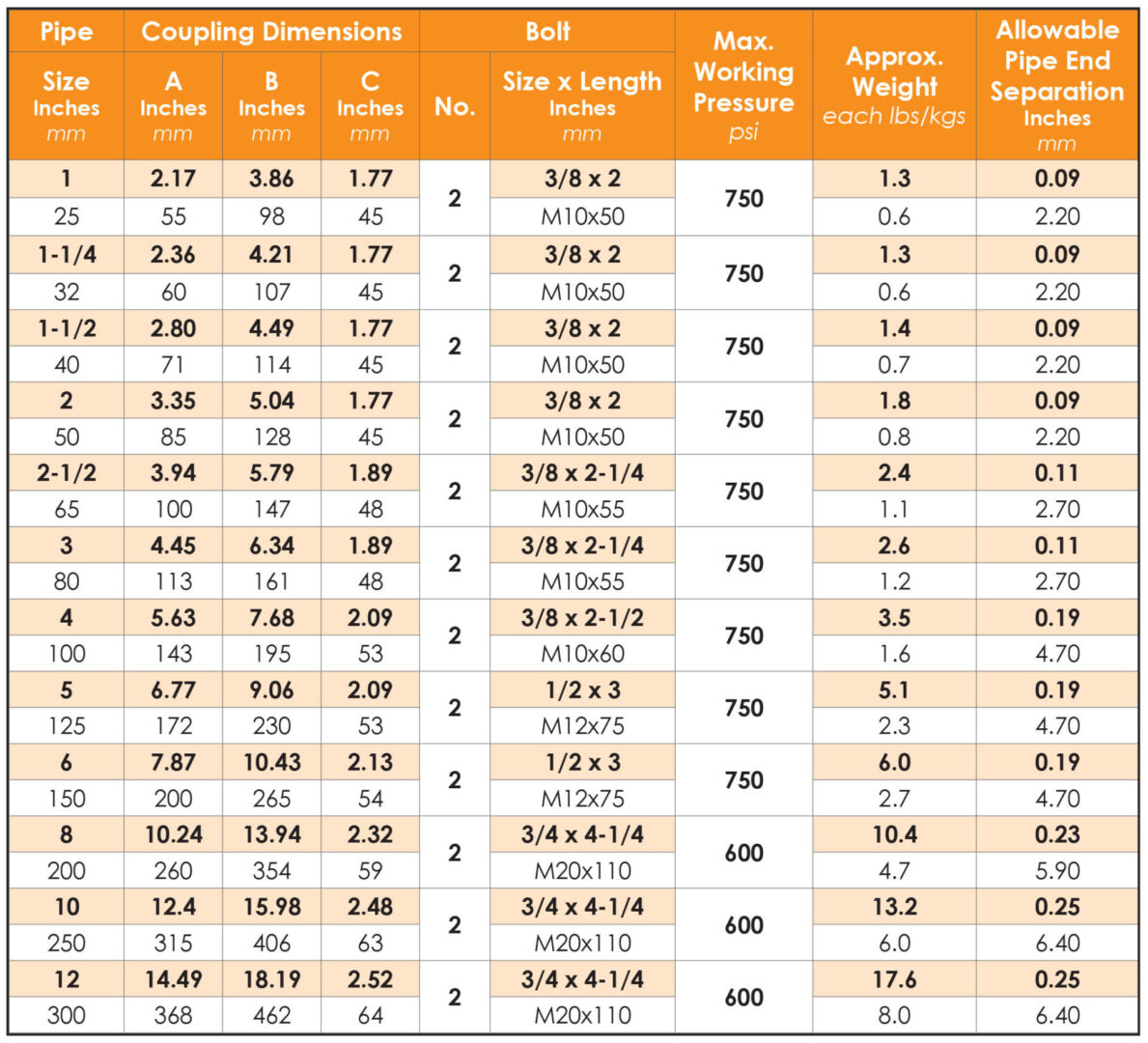

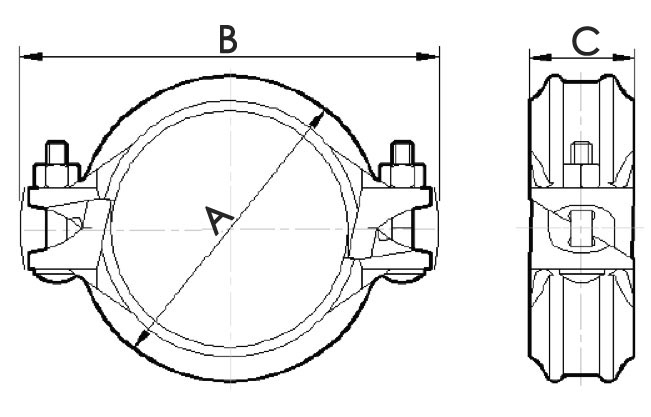

Flexible Couplings

model 15

Standard Weight Flexible Coupling with “C” Gasket

Maximum working pressure depending on schedule of pipe:

1"-8" Sch. 10 pipe 300psi (20.7 bar)

1"-8" Sch. 40 pipe 600psi (41.1 bar)

NSF61 Approved

316 Stainless Steel Couplings conform to ASTM A743/A743M

Type 304 Stainless Steel Trac bolts to ASTM A193 B-8 with heavy-duty washer nuts conforming to ASTM A194 B8, Molybdenum disulfide coated.

Allowable Axial Displacement and Angular Movement (deflection) figures are for roll grooved standard steel pipe. Values for cut grooved pipe will be double that of roll grooved.

Galvanized Rigid Couplings

Ducco GT 4020

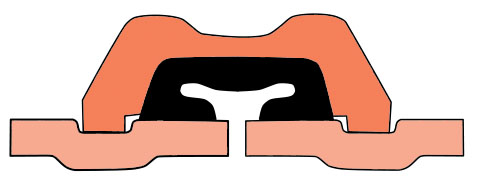

Gasket Recommendations

GroovJoint coupling gaskets are available in many grades of materials and gasket styles.

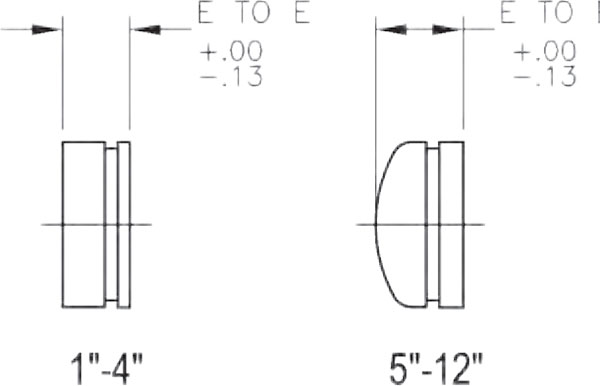

The two most common styles are the C type and E type of gasket. These are pictured below.

“C” style gaskets are the most widely used gaskets when working with grooved couplings and fittings. All GroovJoint grooved couplings come standard with the “C” style gasket installed.

“E” style gaskets commonly referred to as “flush style” are used primarily for vacuum service. The inner lip of the gasket helps reduce the possibility of the gasket cavity filling up with debris and or the distortion of the gasket in vacuum service.

This gasket is available in EPDM material and has the temperature characteristics of the EPDM gasket.

Coupling Gasket Materials

Coupling Gasket EPDM Grade “E” (green stripe)

Temperature range -30F to +230F/-34C to +110C

Recommended for Hot/Cold water service within the specified temperature range. It can also be used with a wide variety of dilute acids, oil-free air and many chemical services.

IAPMO classified in accordance with ANSI/NSF 61 for potable water service from +86F to +180F/ +30C to +82C.

This gasket is not recommended for petroleum or steam service.

Coupling Gasket Nitrile Grade “T” (orange stripe)

Temperature range -20F to +180F /-29C to +82C

Recommended for petroleum products, air with oil vapors, vegetable oils and mineral oils that are within the specified temperature range.

This gasket is not recommended for hot water services over +150F/+66C or for hot dry air over +140F/+60C.

Coupling Gasket Fluor elastomer Grade “O” (blue stripe)

Temperature range +20F to +300F/ -7C to +149C

Recommended for oxidizing acids, petroleum oil products, hydrocarbons, hydraulic fluids and air with hydrocarbons.

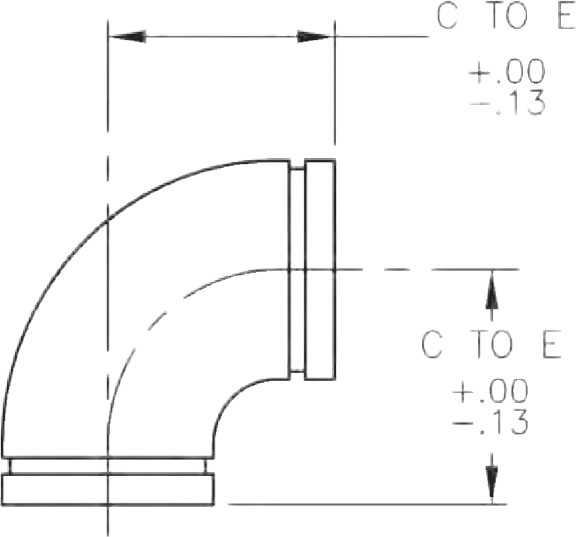

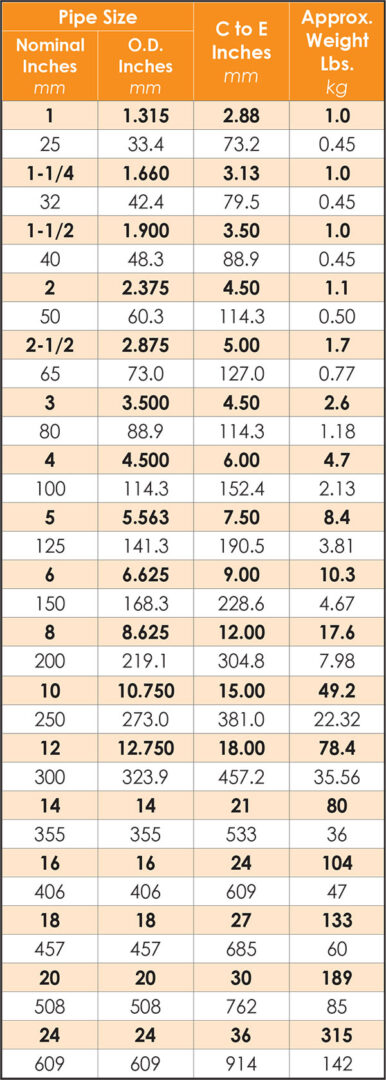

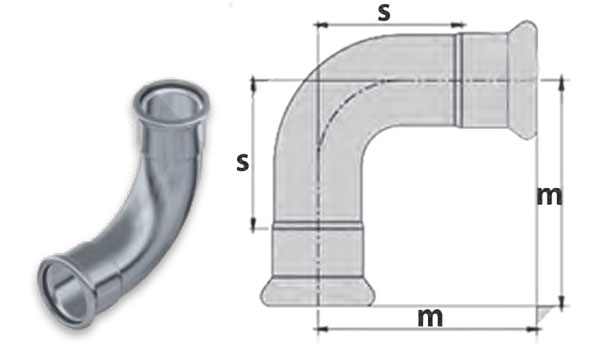

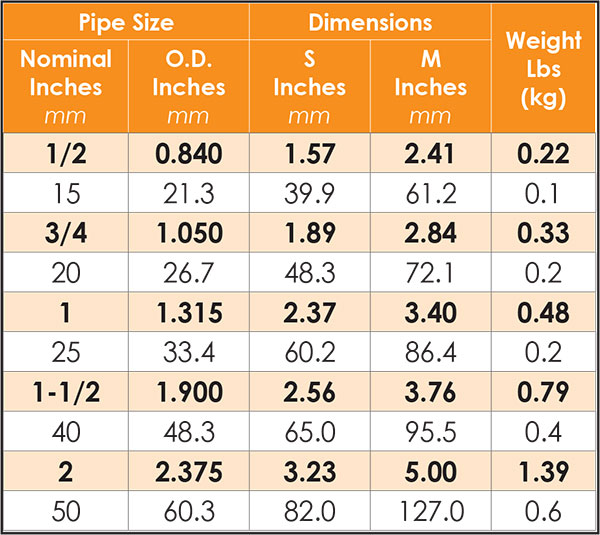

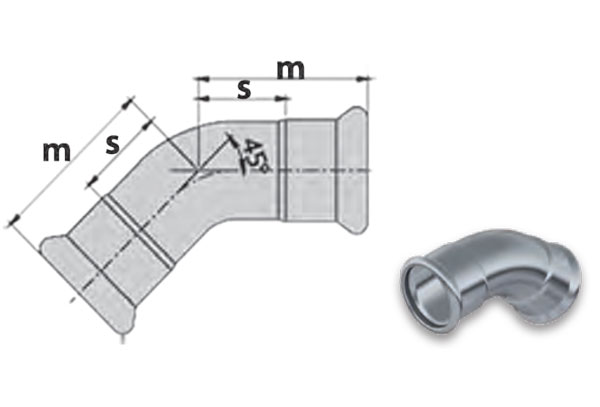

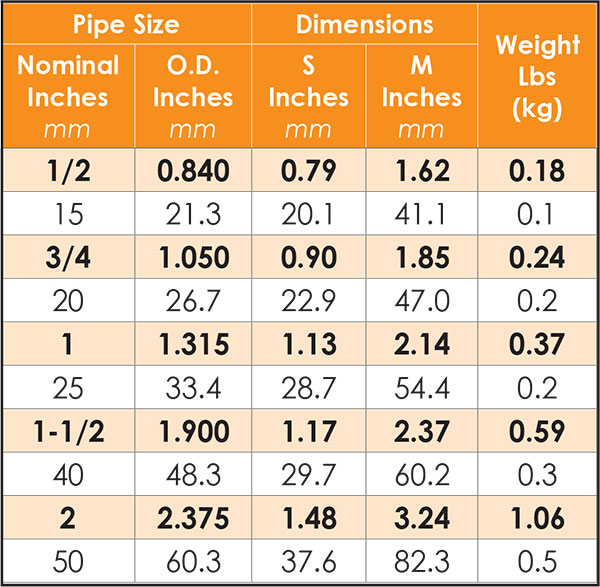

90º Elbows

part #469

Sch. 10 Stainless Steel

Other options available:

MAXIMUM WORKING PRESSURE – See specific data sheet for rating of coupling in use.

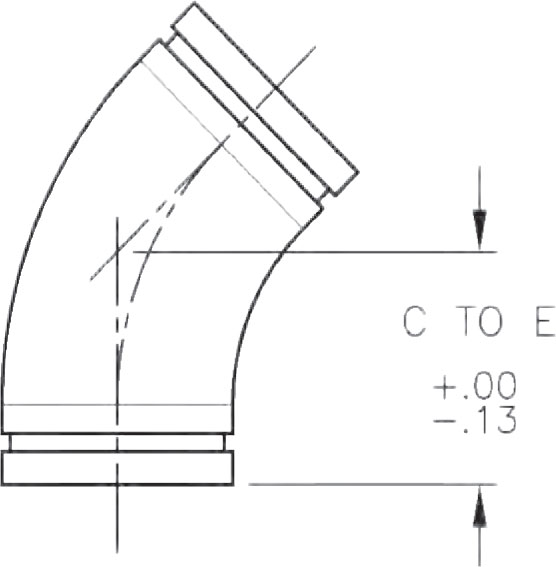

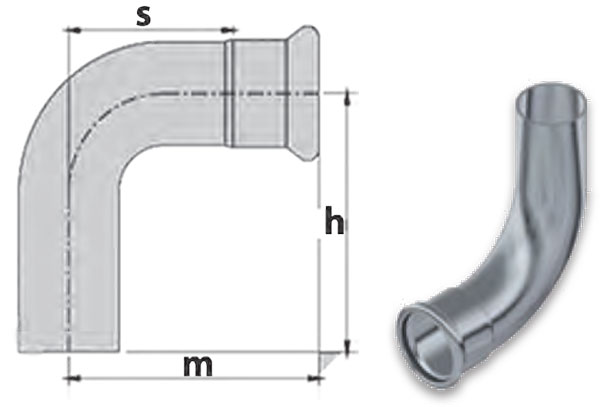

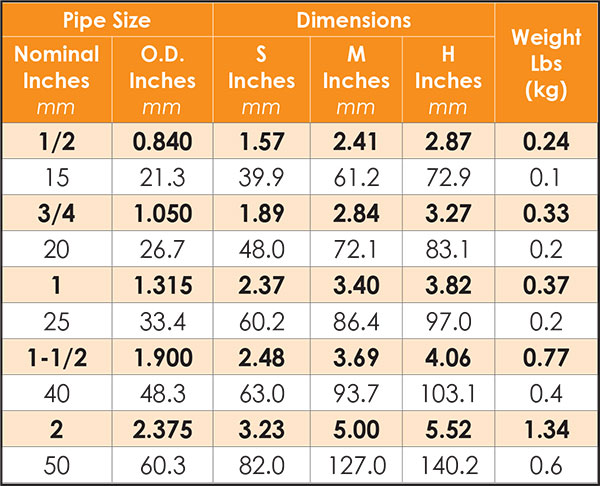

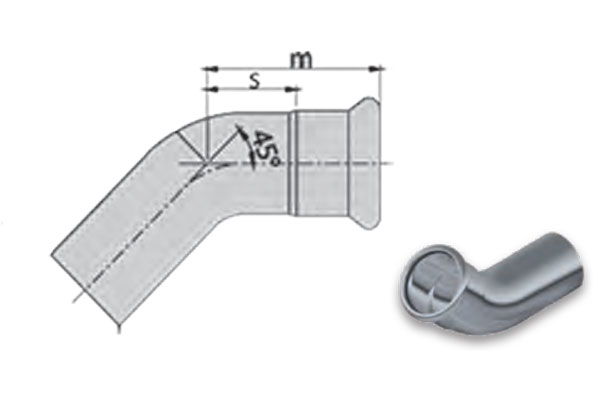

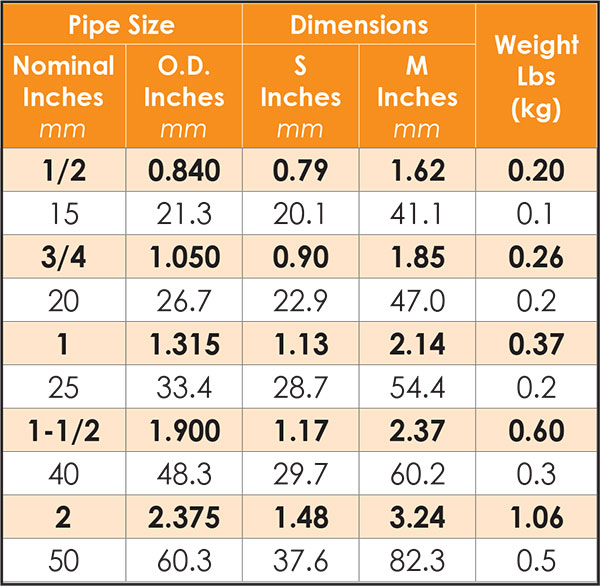

45º Elbows

part #464

Sch. 10 Stainless Steel

MAXIMUM WORKING PRESSURE – See specific data sheet for rating of coupling in use.

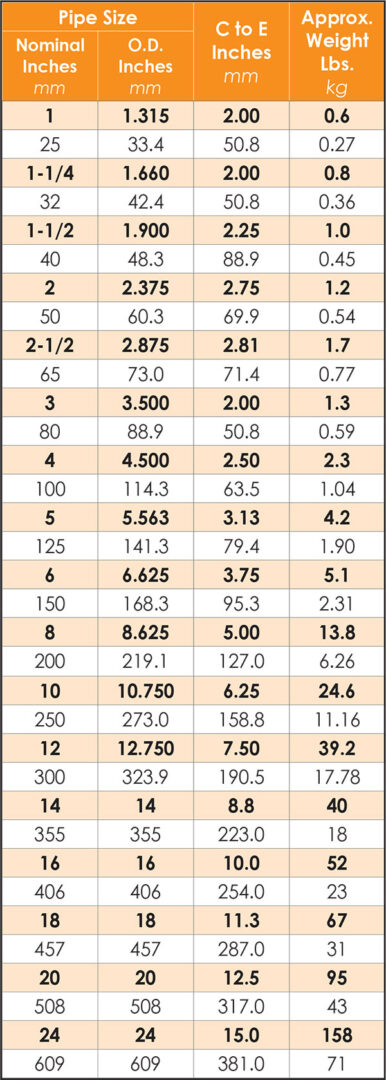

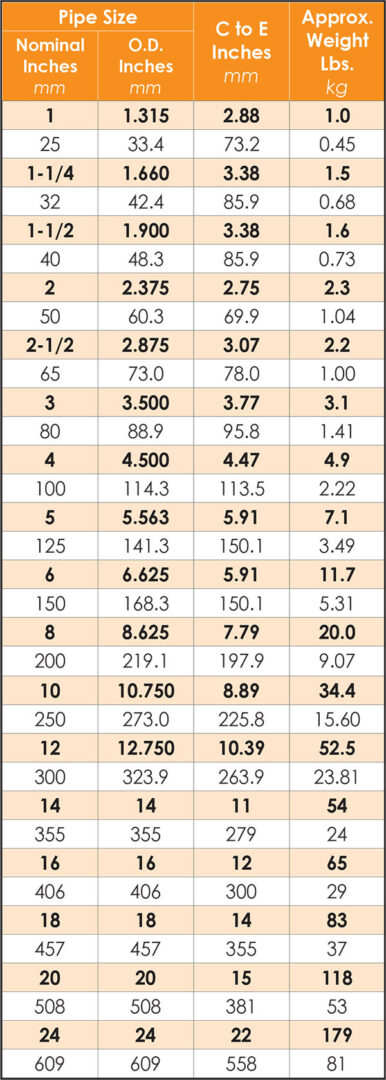

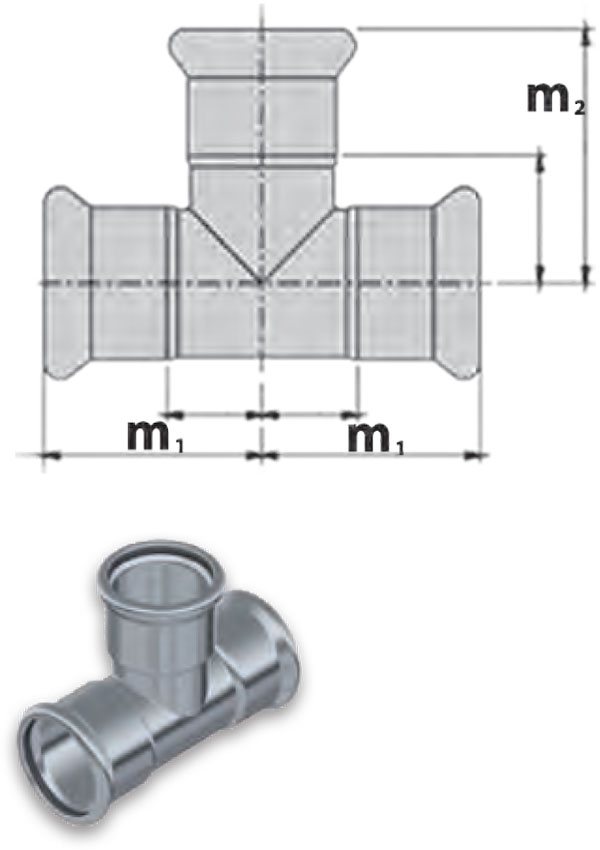

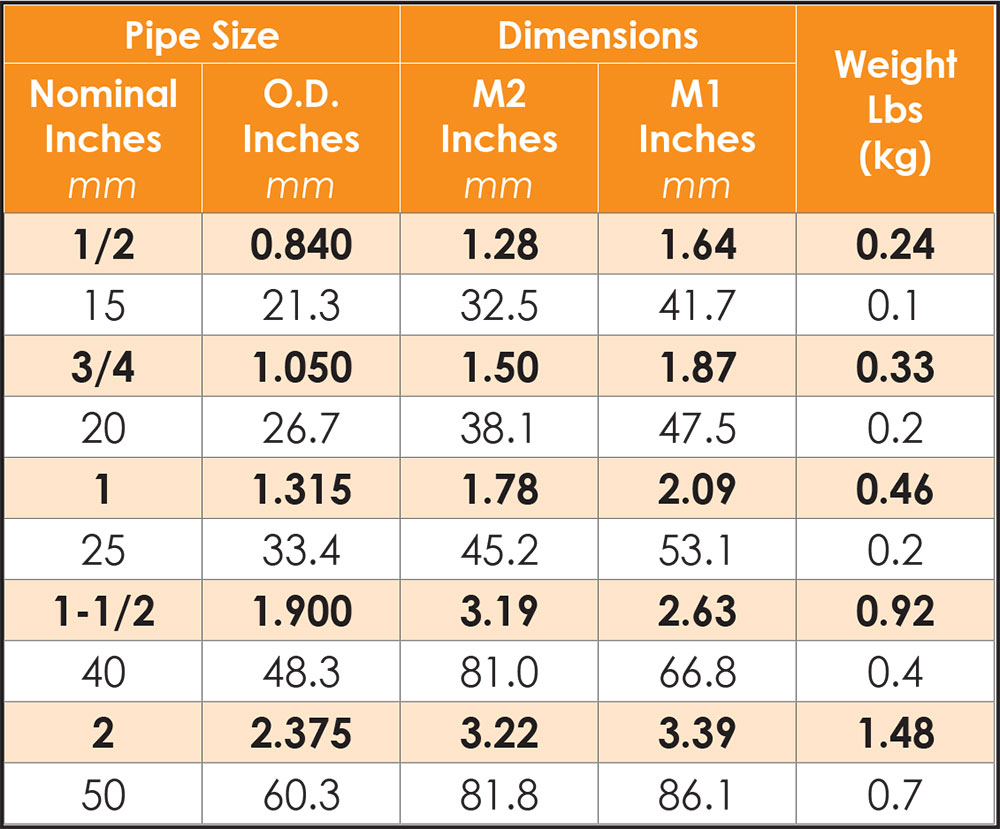

Tees

part #46T

Sch. 10 Stainless Steel

MAXIMUM WORKING PRESSURE – See specific data sheet for rating of coupling in use.

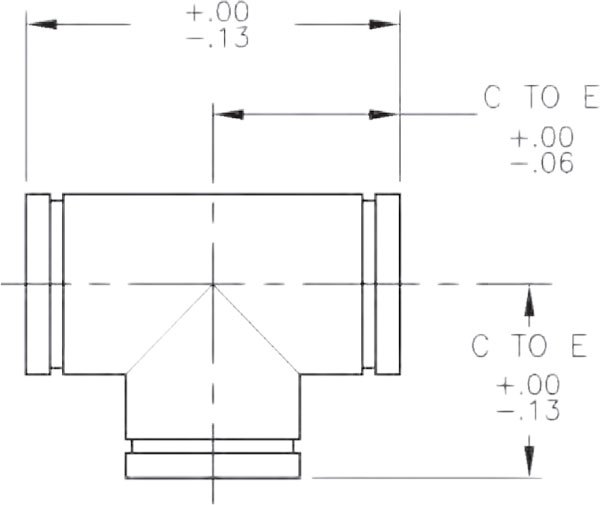

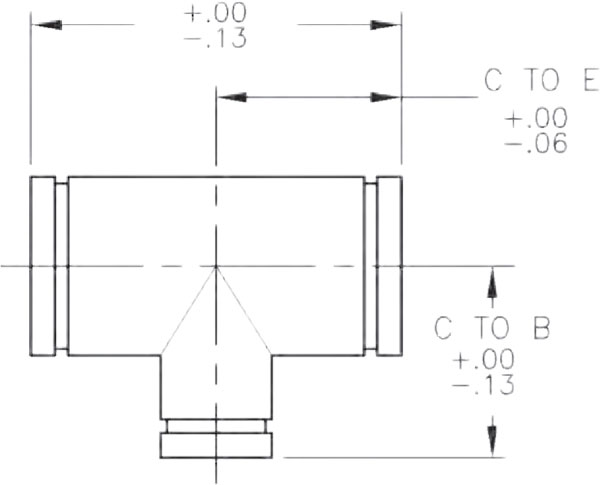

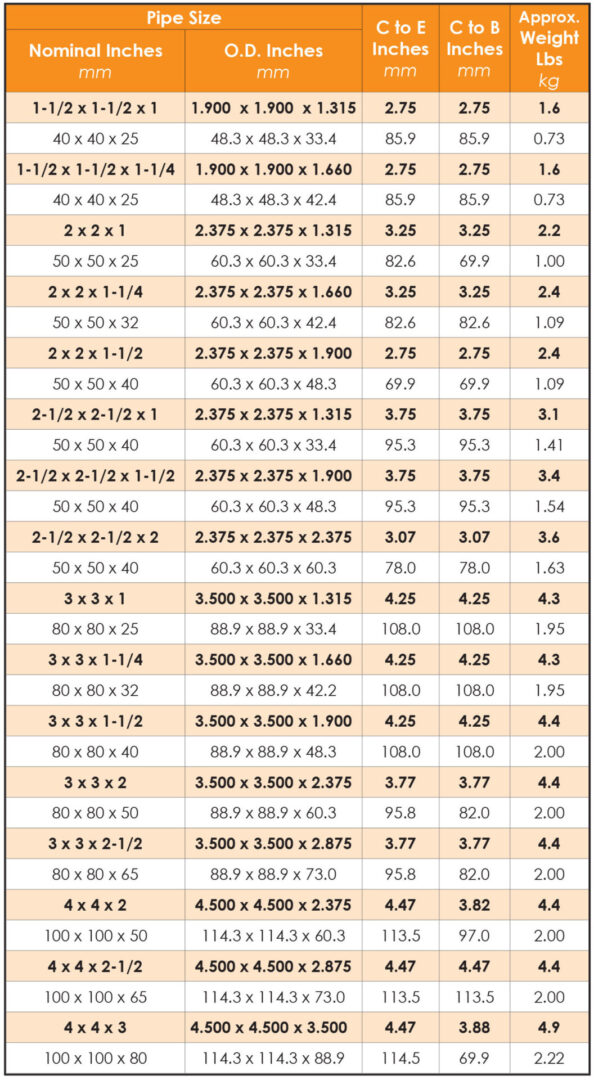

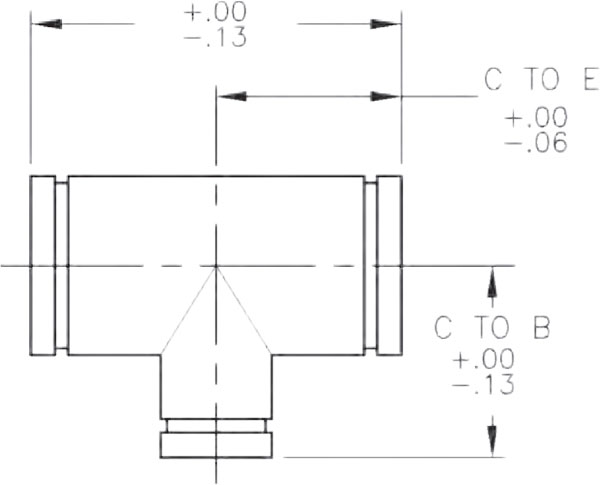

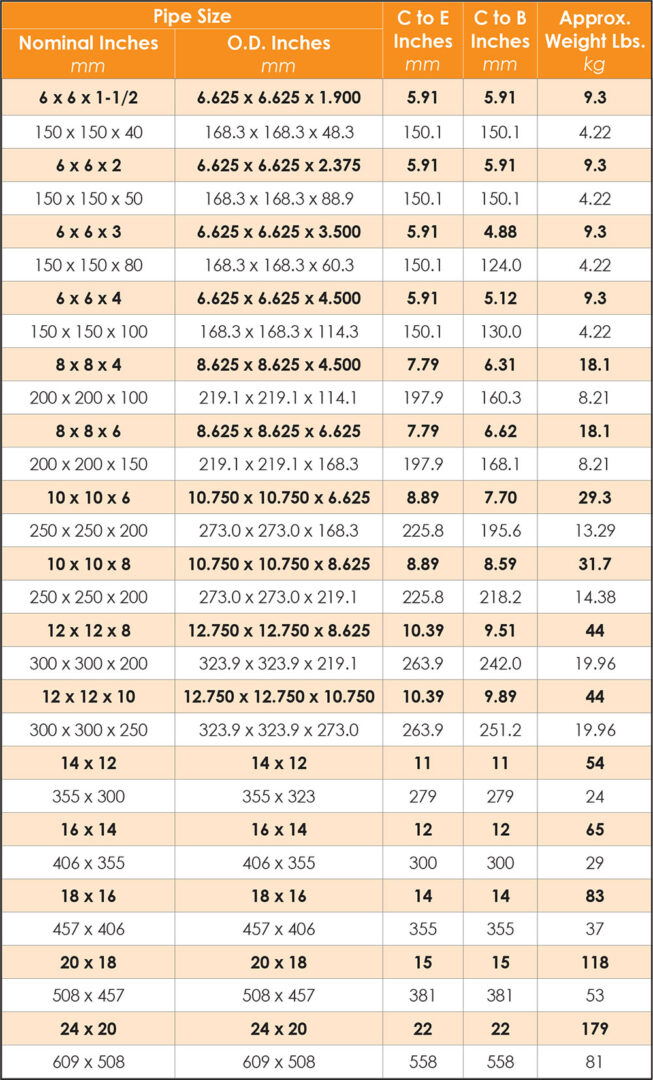

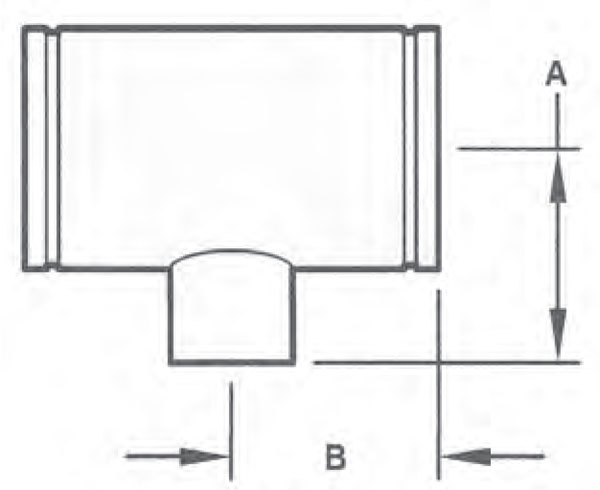

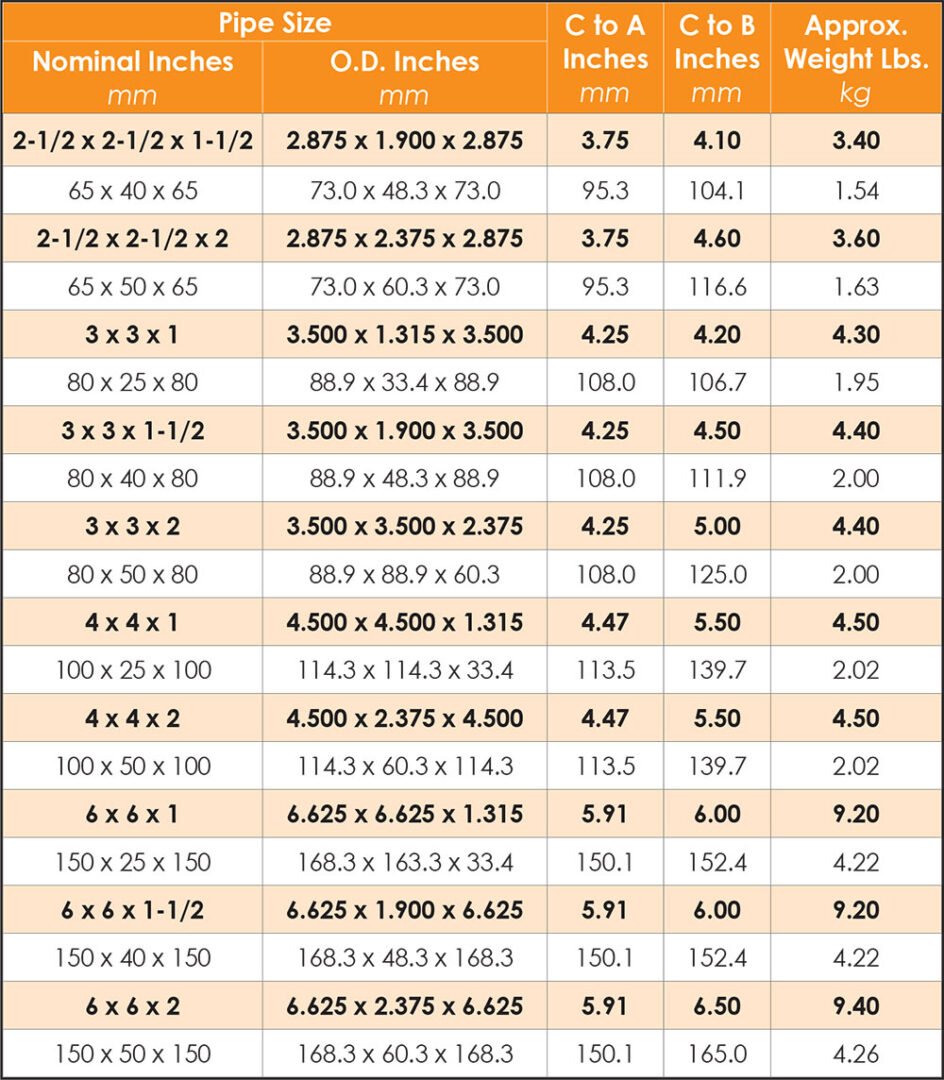

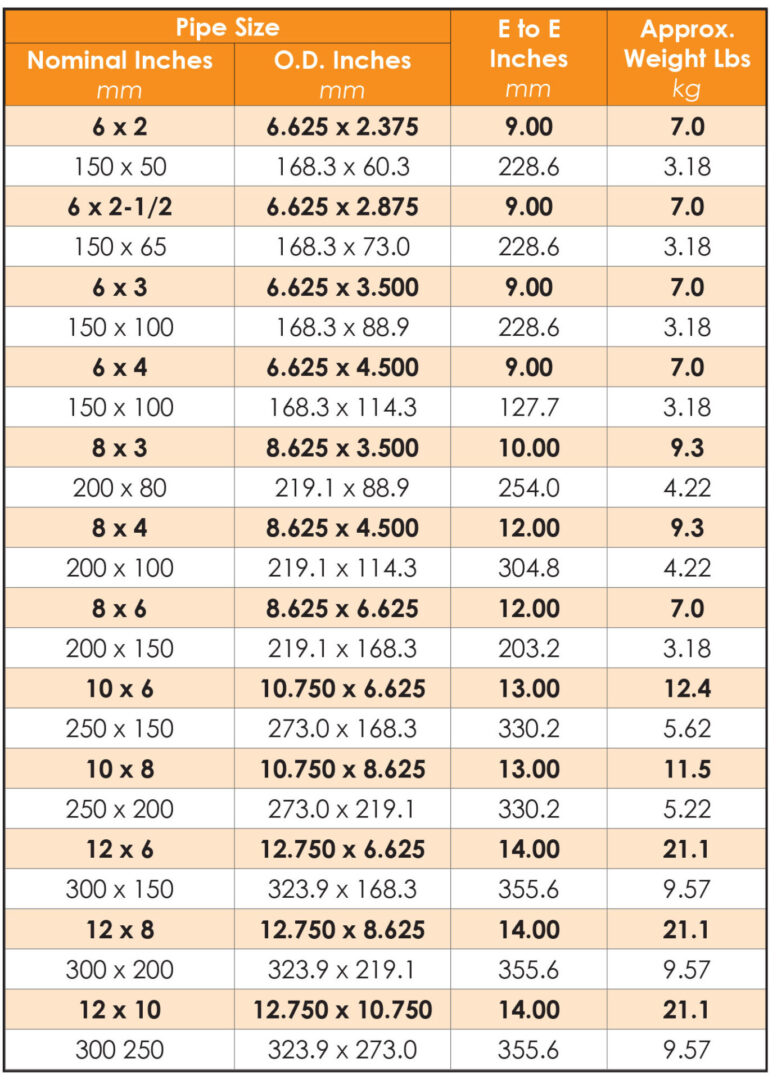

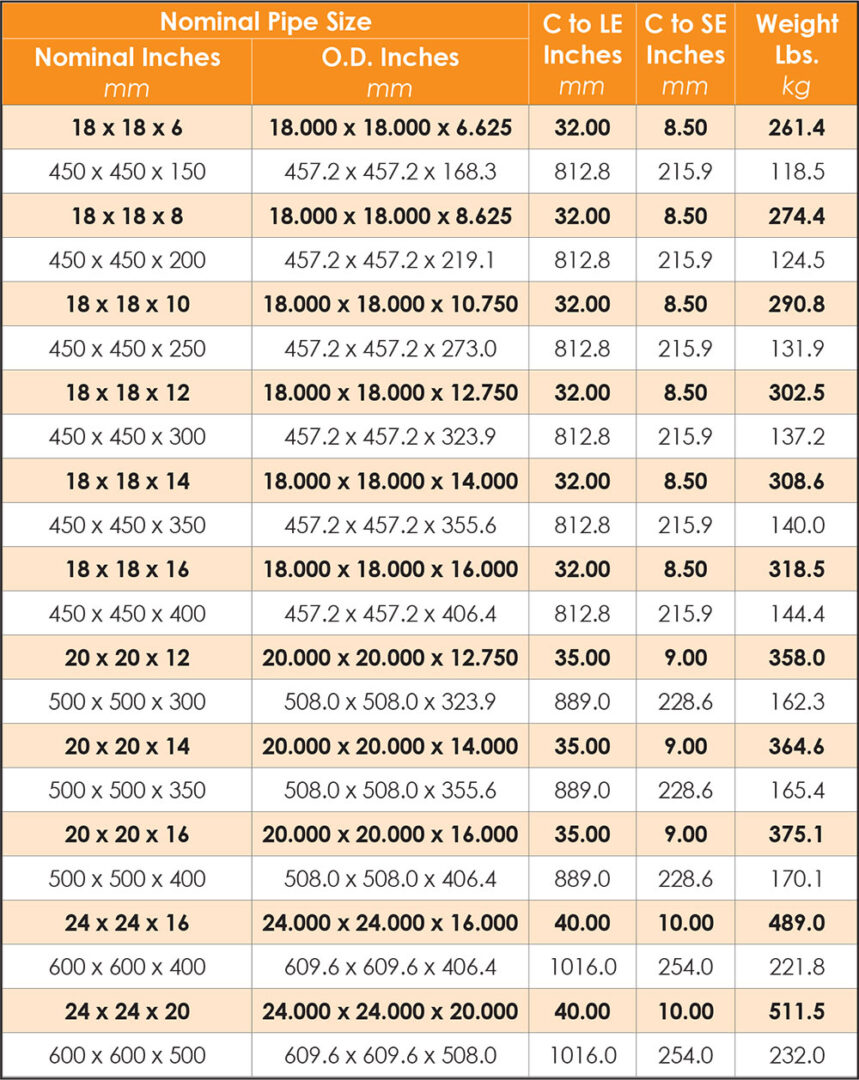

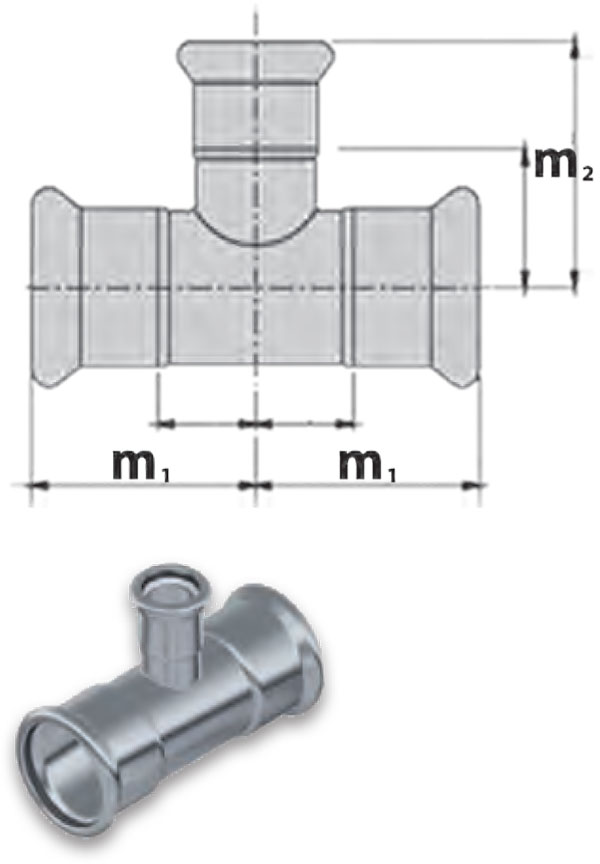

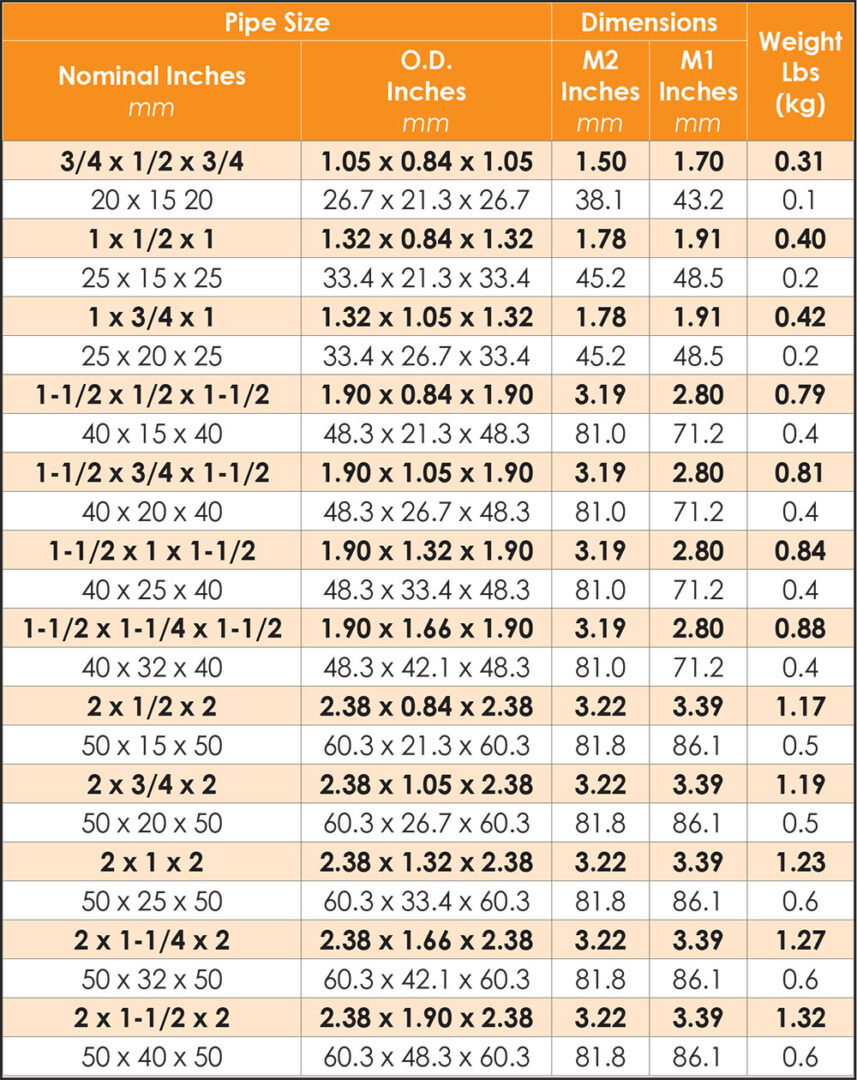

Reducing Tees

part #46RT

Sch. 10 Stainless Steel

MAXIMUM WORKING PRESSURE – See specific data sheet for rating of coupling in use.

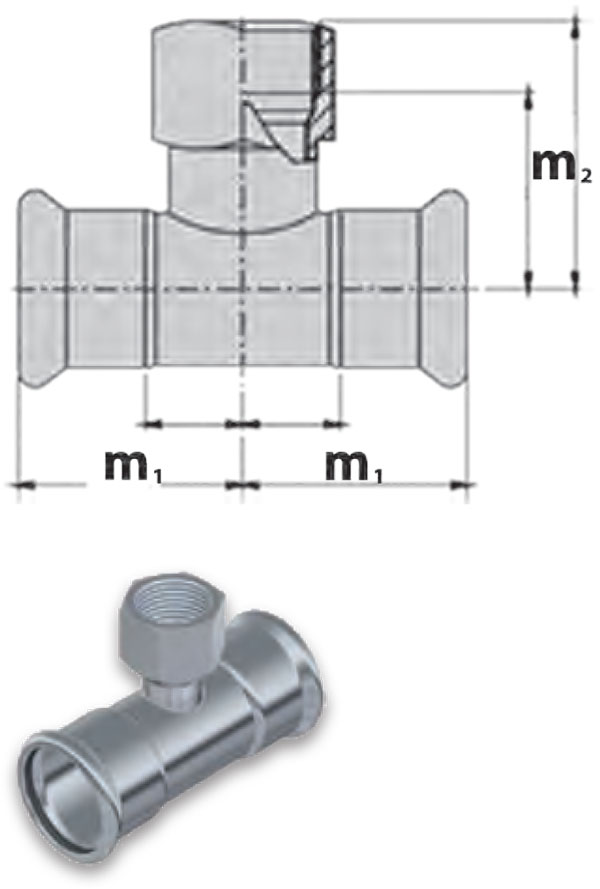

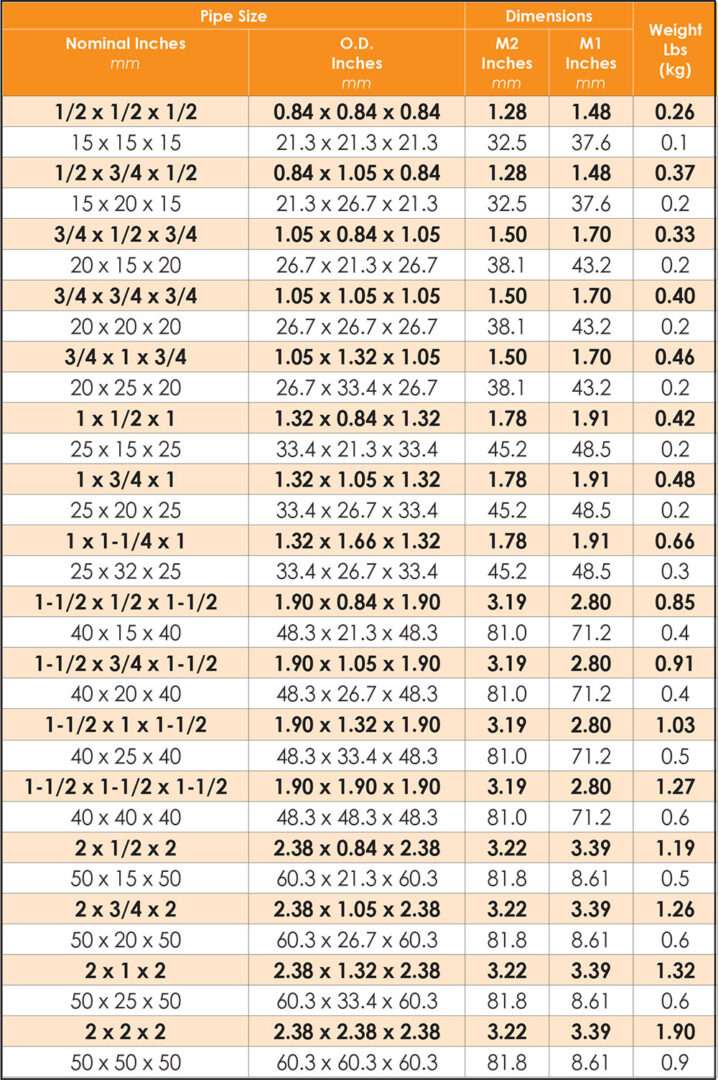

Reducing Tees

part #46RT

Sch. 10 Stainless Steel

MAXIMUM WORKING PRESSURE – See specific data sheet for rating of coupling in use.

Grooved by Press Reducing Tees

part #464

Sch. 10 Stainless Steel

Groove by Press Tees

This is an excellent transition for joining grooved and press fittings together. While the runs are roll grooved, the branch is a plain end finish allowing for a press fitting

to be attached using the appropriate press tool.

Other sizes available upon request. Other branch configurations are available as well. Male thread or female thread are just a few options available.

MAXIMUM WORKING PRESSURE – See specific data sheet for rating of coupling in use.

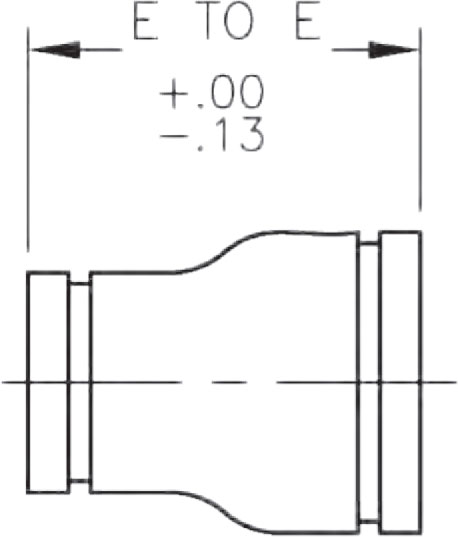

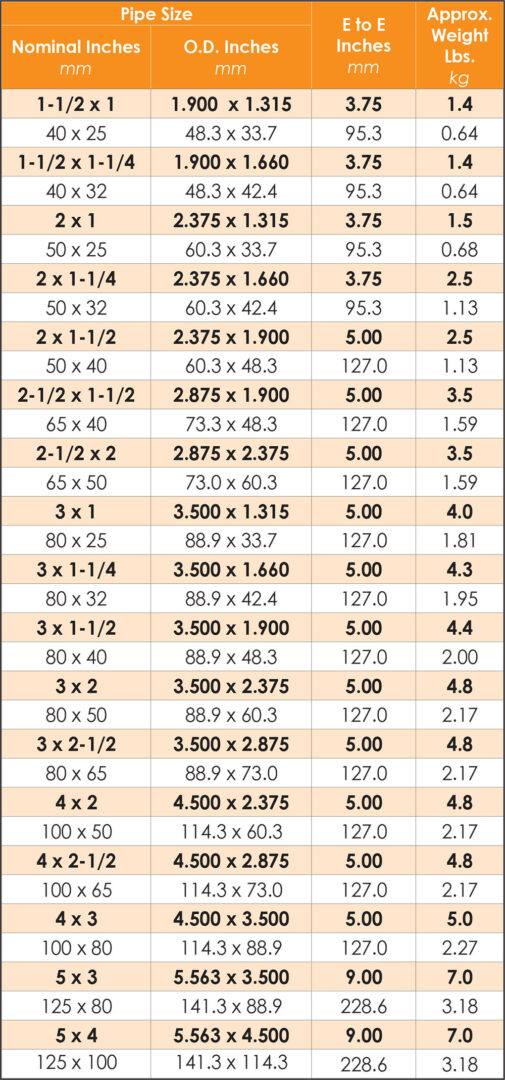

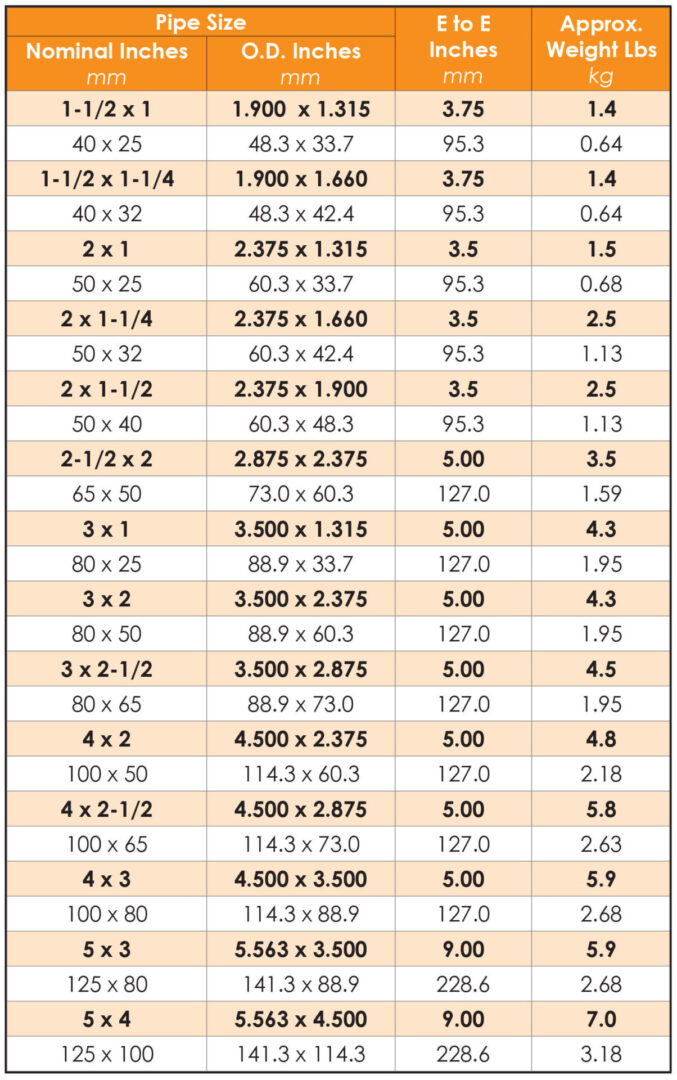

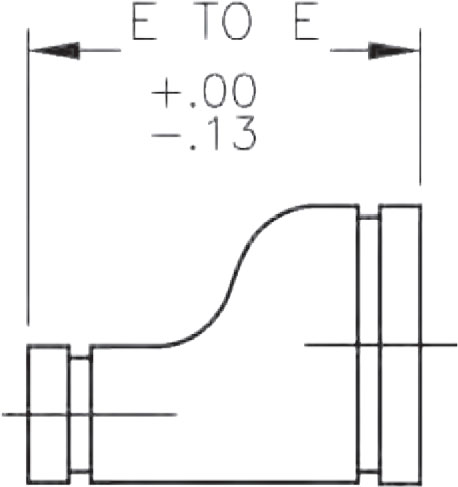

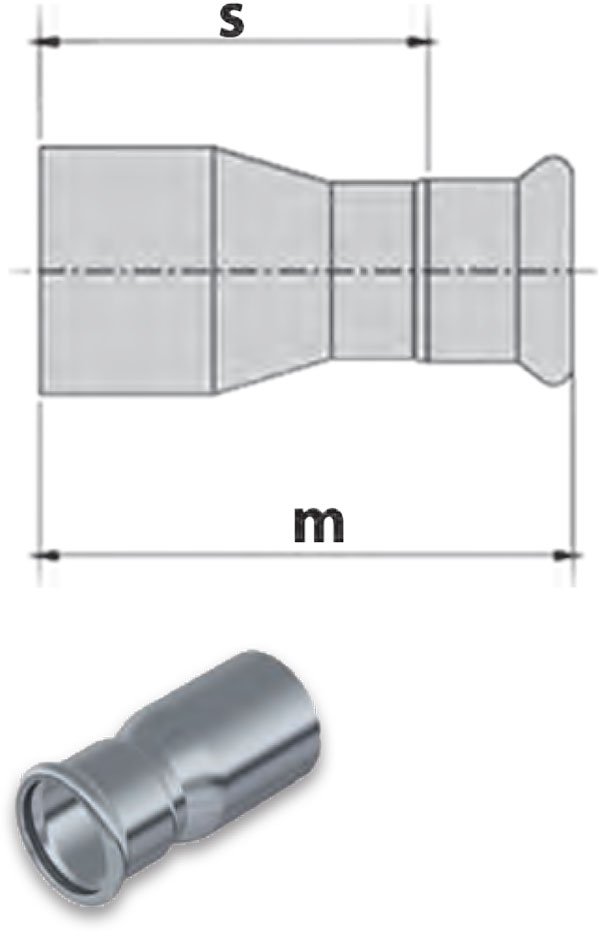

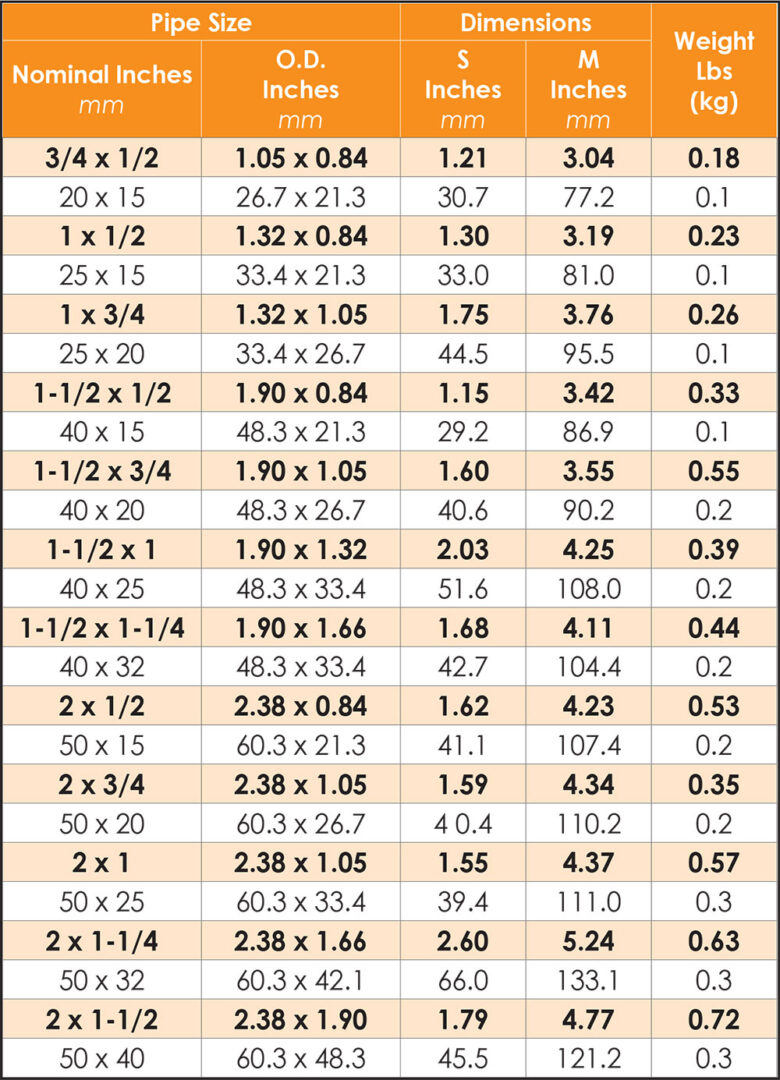

Concentric Reducers

part #46C

Sch. 10 Stainless Steel

MAXIMUM WORKING PRESSURE – See specific data sheet for rating of coupling in use.

Concentric Reducers

part #46C

Sch. 10 Stainless Steel

MAXIMUM WORKING PRESSURE – See specific data sheet for rating of coupling in use.

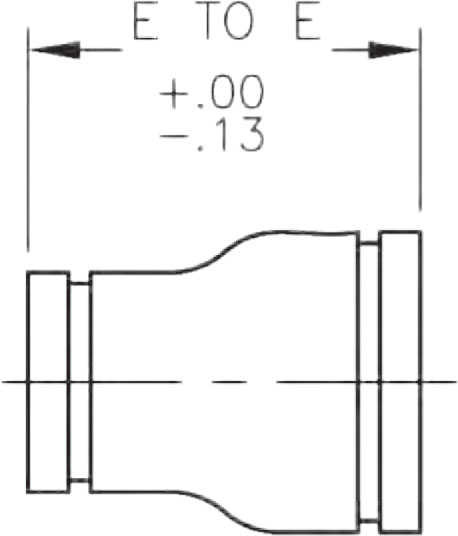

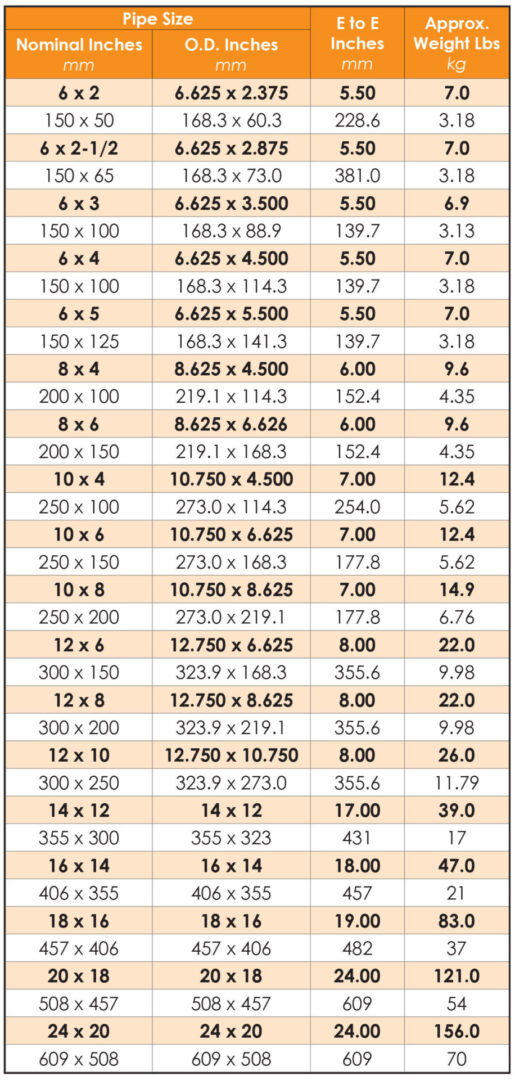

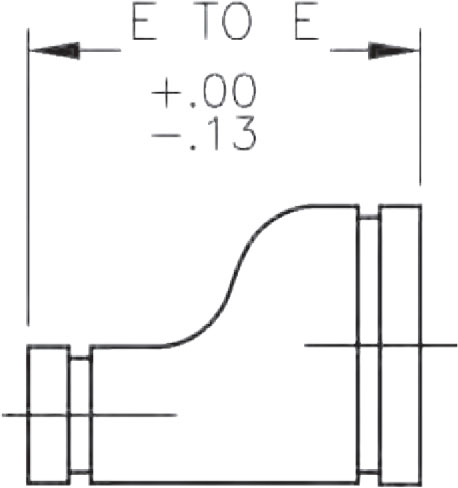

Eccentric Reducers

part #46E

Sch. 10 Stainless Steel

MAXIMUM WORKING PRESSURE – See specific data sheet for rating of coupling in use.

Eccentric Reducers

part #46E

Sch. 10 Stainless Steel

MAXIMUM WORKING PRESSURE – See specific data sheet for rating of coupling in use.

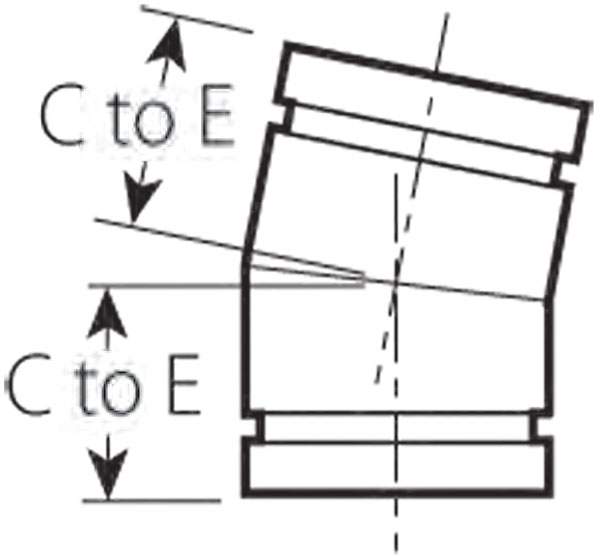

11¼° Elbows

figure 461

Sch. 10 Stainless Steel

MAXIMUM WORKING PRESSURE – See specific data sheet for rating of coupling in use.

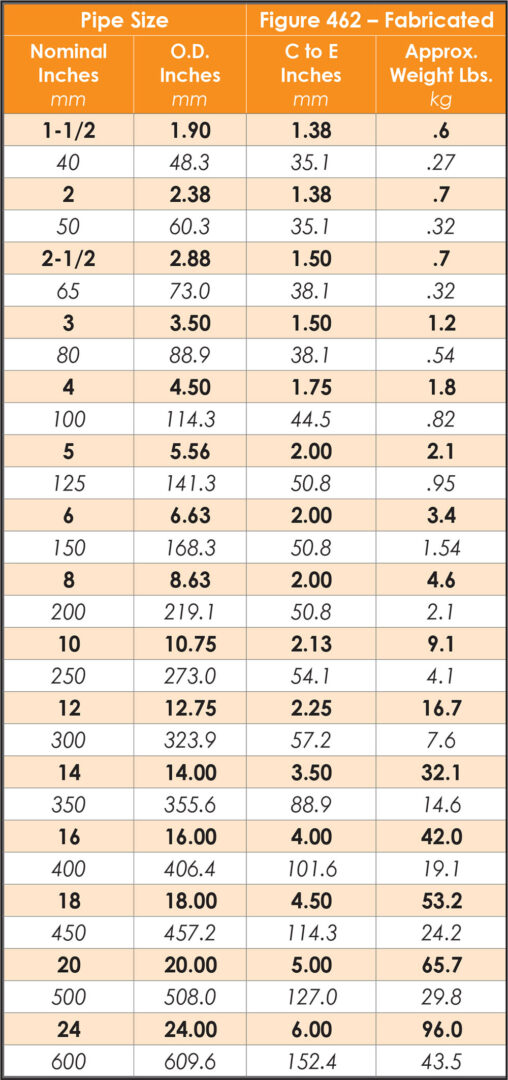

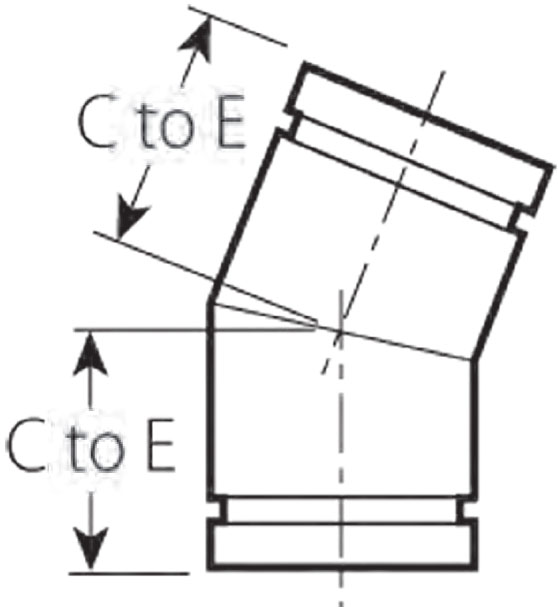

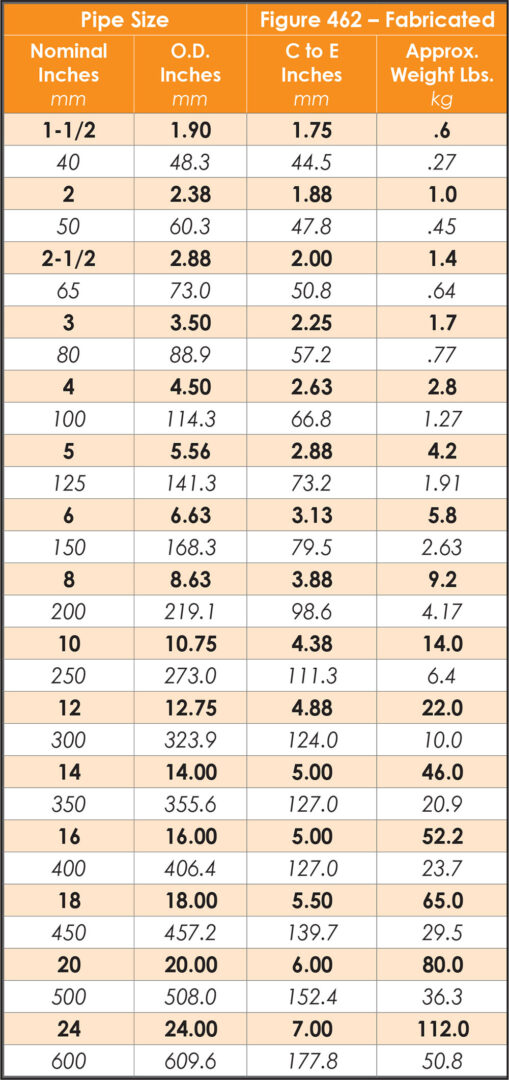

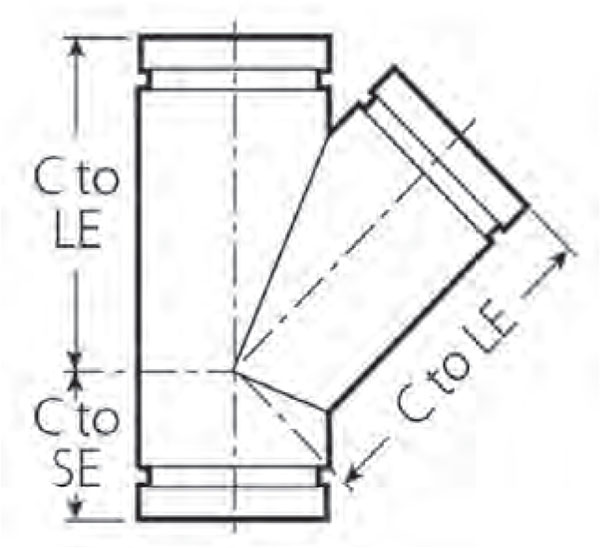

22½° Elbows

figure 462

Sch. 10 Stainless Steel

MAXIMUM WORKING PRESSURE – See specific data sheet for rating of coupling in use.

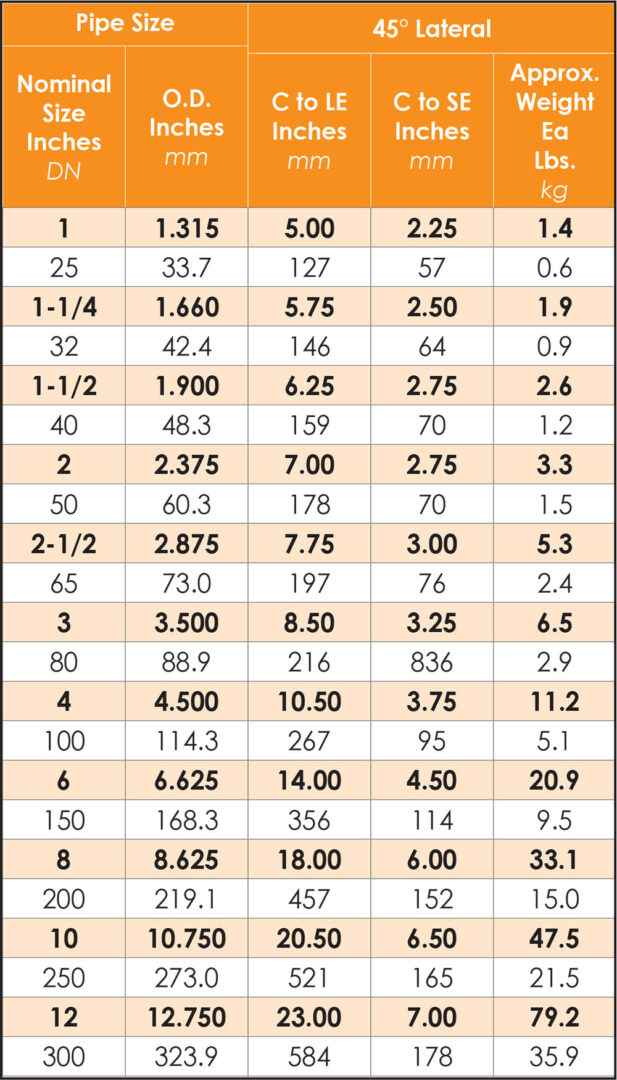

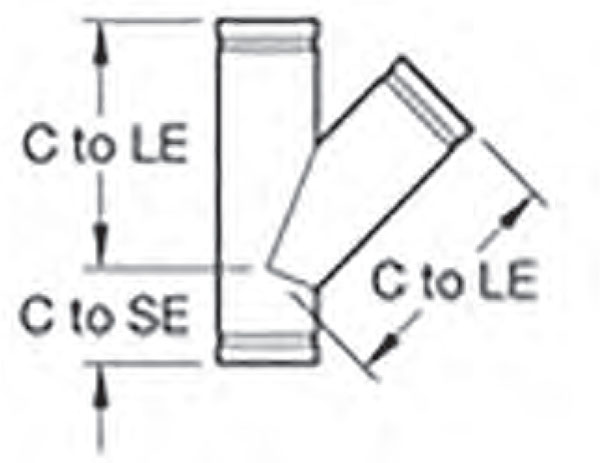

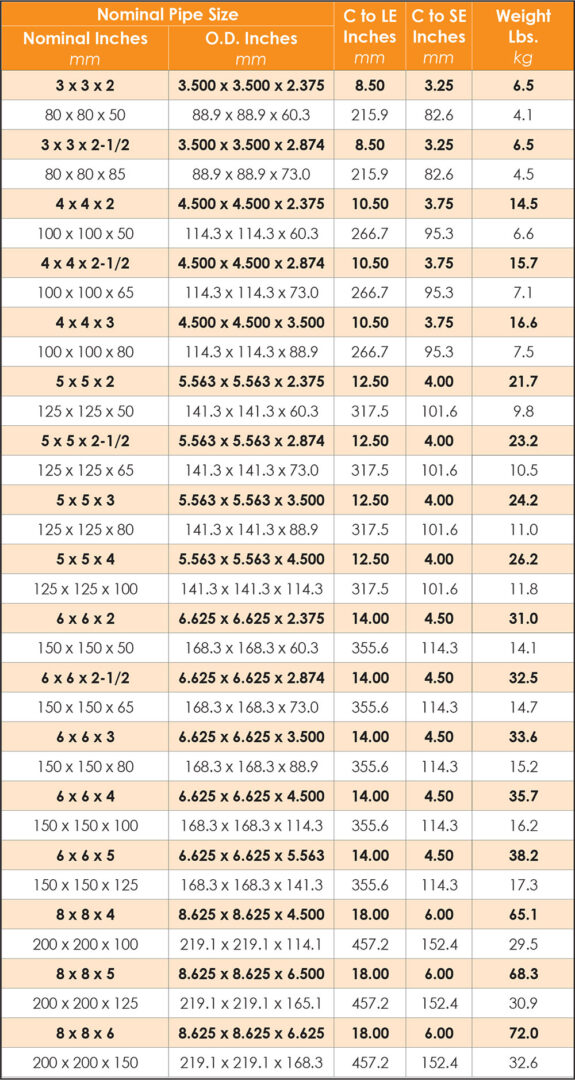

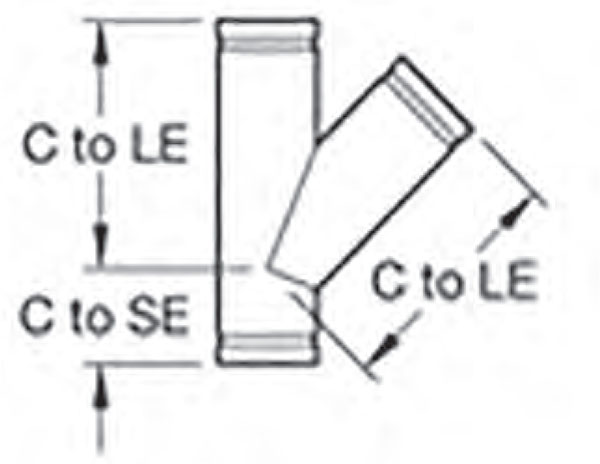

45º Laterals

part #46LAT

Sch. 10 Stainless Steel

45º Reducing Laterals

part #46LAT

Sch. 10 Stainless Steel

Reducing Laterals can be supplied w/MPT or FPT Branch or with a Plain End for Press Fittings

Other Reductions available upon request

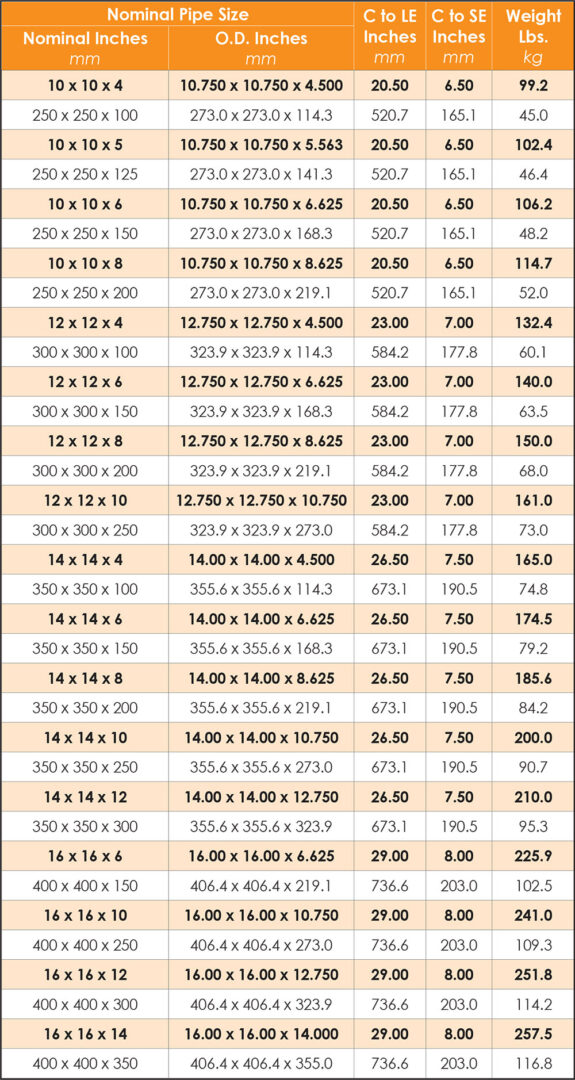

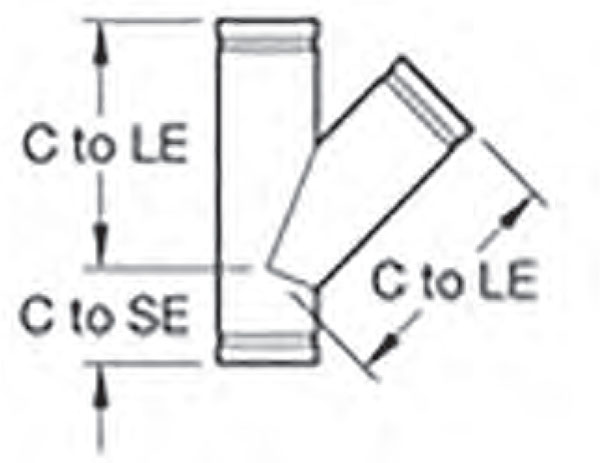

45º Reducing Laterals

part #46LAT

Sch. 10 Stainless Steel

Reducing Laterals can be supplied w/MPT or FPT Branch or with a Plain End for Press Fittings

Other Reductions available upon request

45º Reducing Laterals

part #46LAT

Sch. 10 Stainless Steel

Reducing Laterals can be supplied w/MPT or FPT Branch or with a Plain End for Press Fittings

Other Reductions available upon request

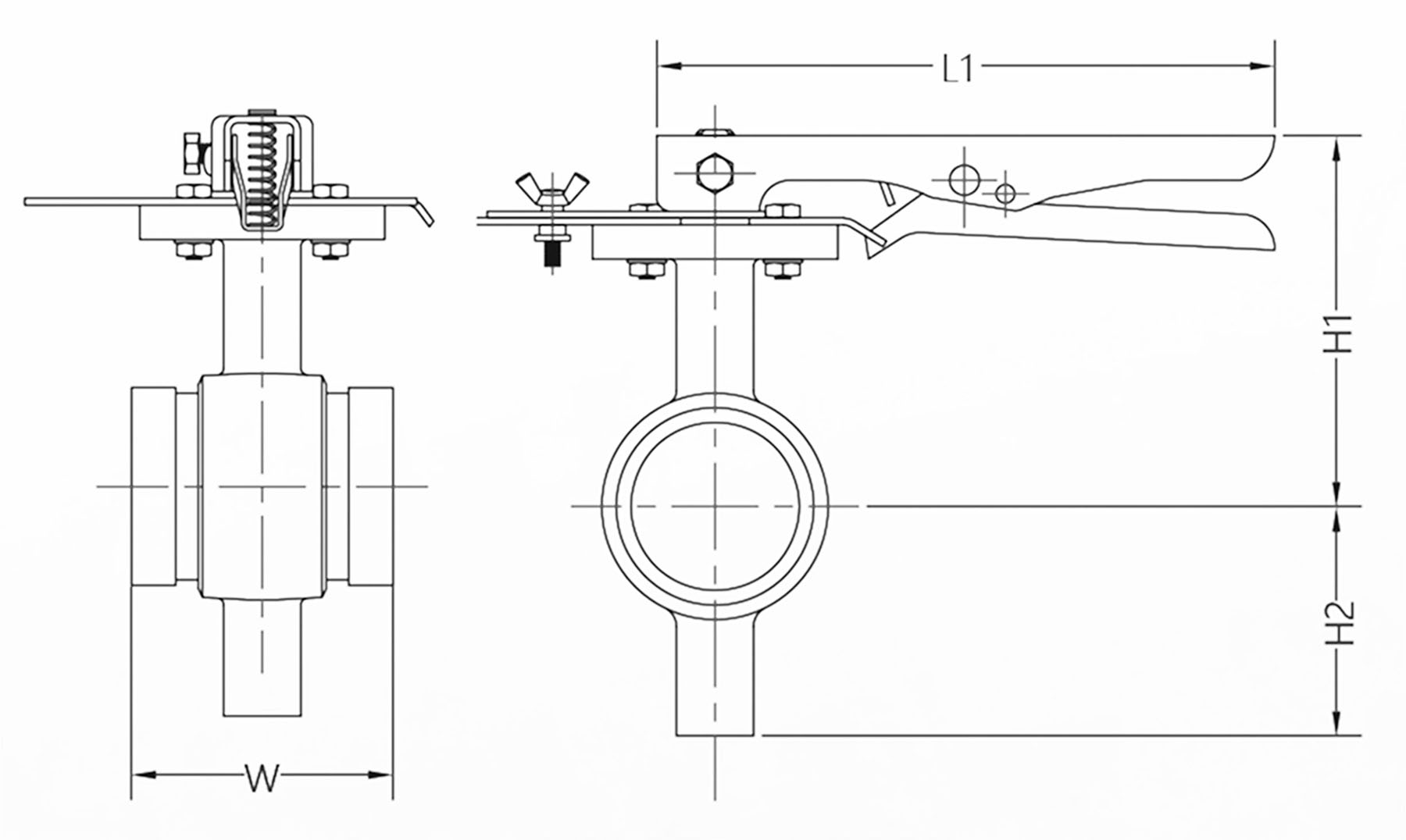

316 Stainless Steel Butterfly Valve

Model 9200

with resilient seated disc

The GroovJoint Model 9200 stainless steel, grooved-end (ANSI/AWWA C-606) butterfly valve provides bubble-tight shut-off at full-rated working pressure. The 9200 is rated to 300 psi and bi-directional. It is available in sizes 2"-8".

The valve features a 10-position epoxy-coated lever handle with 10-position and infinitely-variable settings with memory-stop, making it suitable for both throttling and system balancing. The extended neck allows for up to 2 inches of insulation, and the ISO mounting pad allows easy installation of an optional gear-operator or pneumatic/electric actuators.

The 9200 butterfly valve is available with either an EPDM or NBR Encapsulated Disc. The max temperature is 230ºF and rated for both indoor and outdoor applications.

A manufacturer's 2-year limited warranty applies.

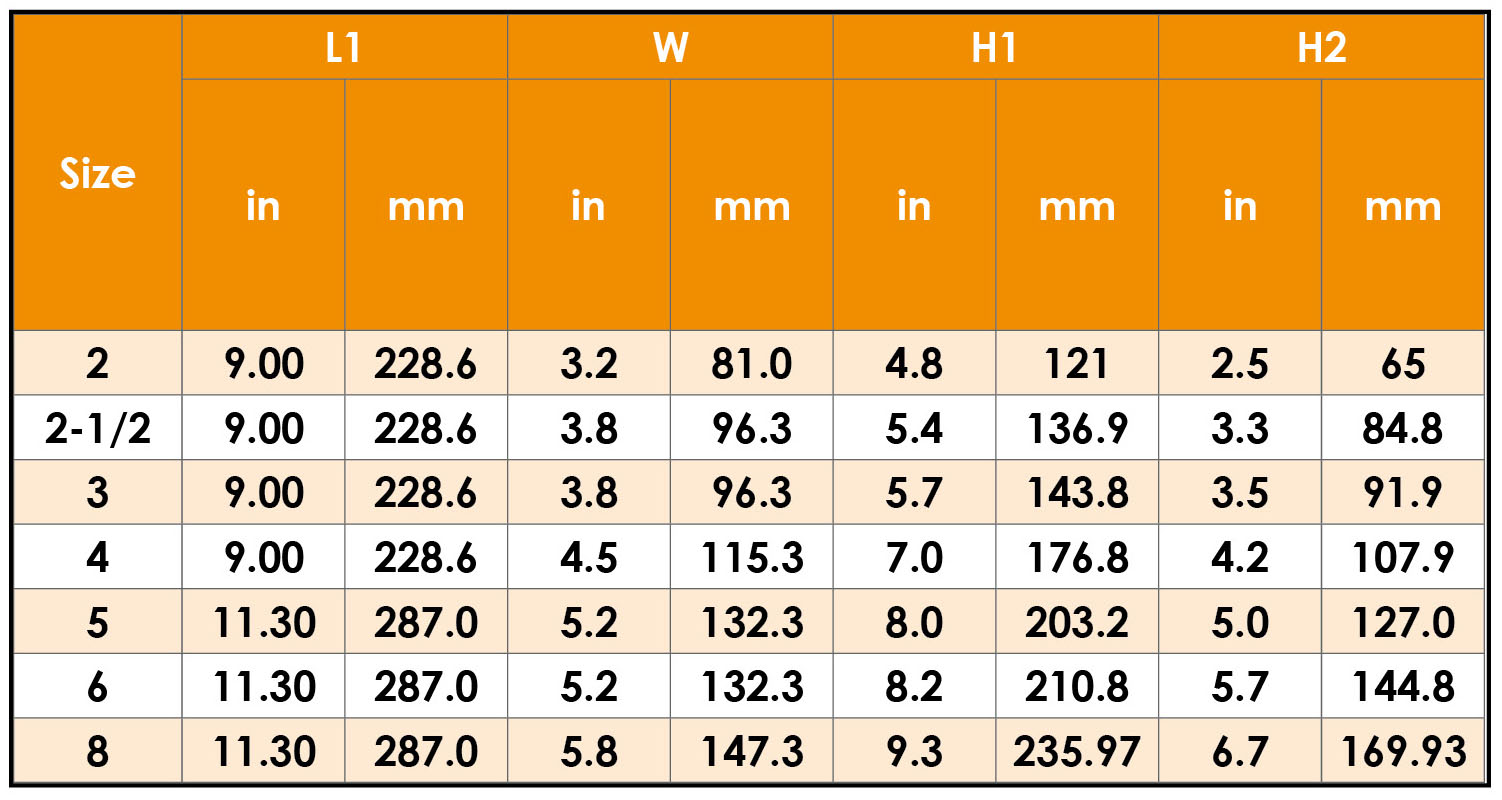

End Caps

part #46CAP

*Dished cap

Sch. 10 Stainless Steel

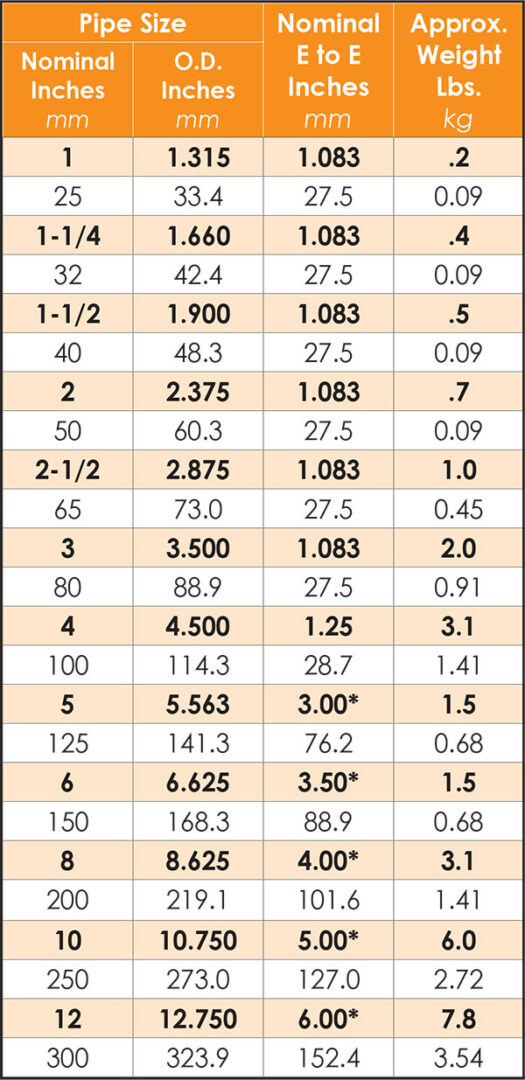

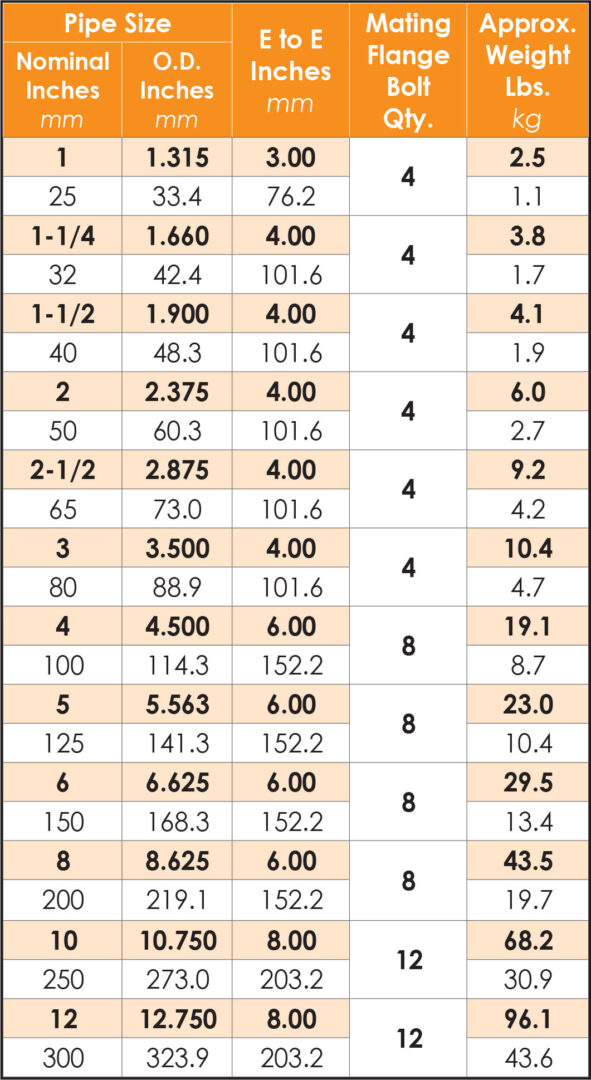

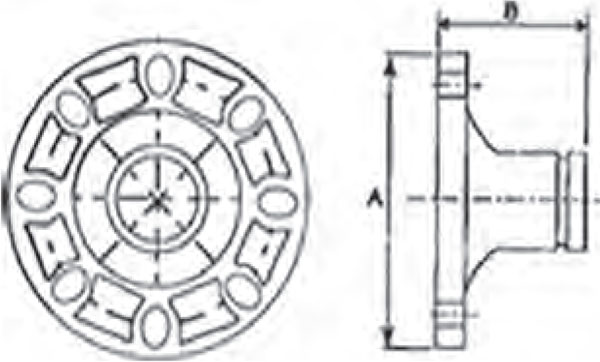

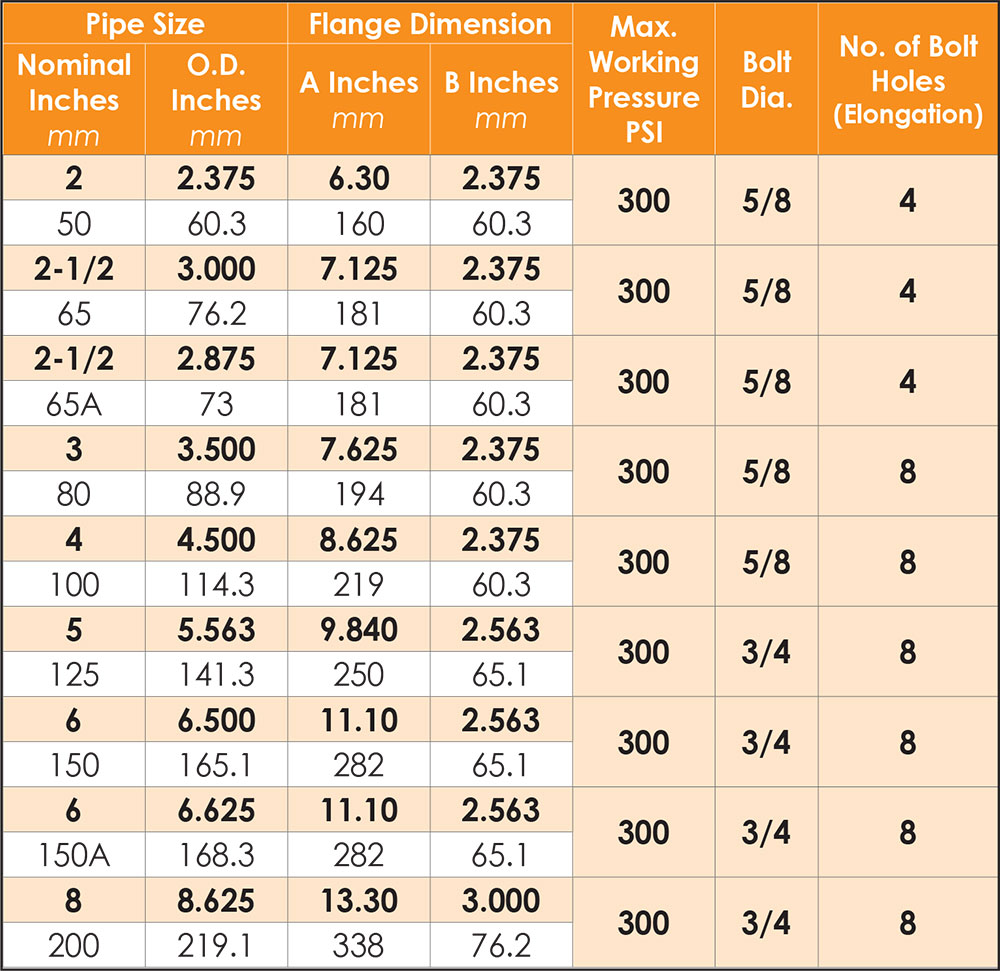

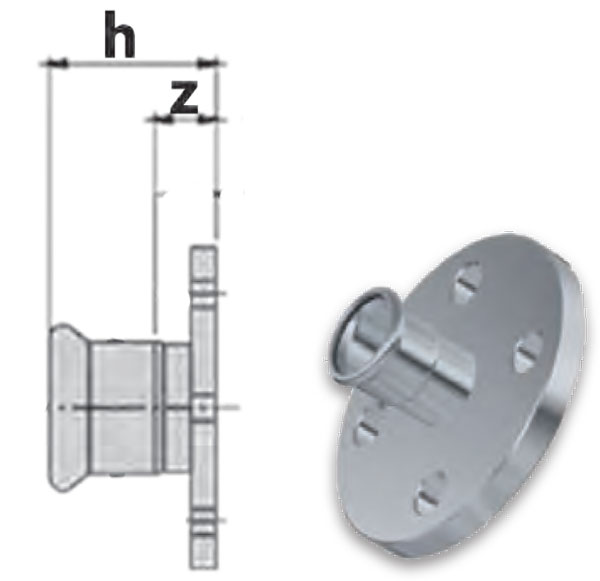

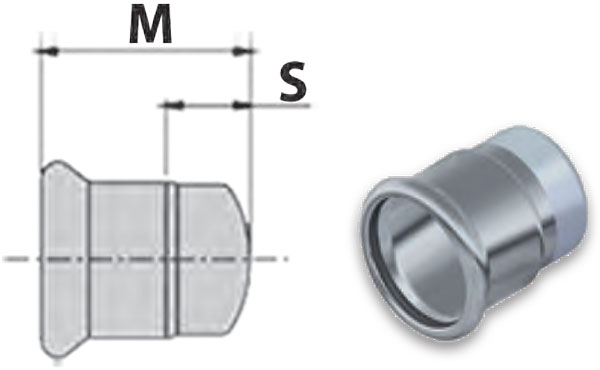

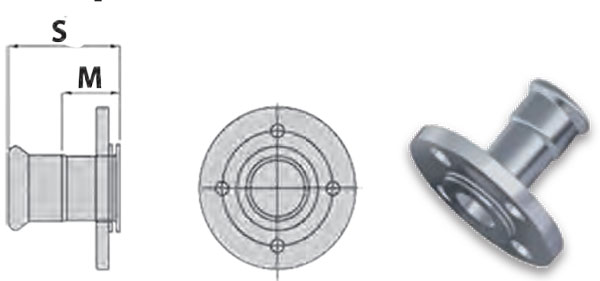

Flange Adaptors

part #46F

Flange adaptors are available in both ANSI

dimensions as well as PN10 and PN16

Sch. 10 Stainless Steel

MAXIMUM WORKING PRESSURE – See specific data sheet for rating of coupling in use.

316 Stainless Steel Cast Flange Adaptors

part #46FPN

Sch. 10 Stainless Steel

Standard ANSI 150, J1S, 10K, PN16.

MAXIMUM WORKING PRESSURE – See specific data sheet for rating of coupling in use.

Schedule 40 Stainless Steel Fittings

As part of our product offering, GroovJoint stocks Schedule 40 Stainless Steel Fittings in both 304L and 316L grades.

Sizes range from 1-1/2"-12".

All Sch. 40 fittings are designed to be as close to the Sch. 10 sizes where possible. All dimensions are available on request.

This product can be offered in either a roll grooved end or a cut grooved end (depending on the customers needs).

We also fabricate Sch. 40 fittings.

Some of those fittings include:

Model 15 Flexible Couplings and Model 24 Rigid Couplings may be used with Schedule 40 fittings and pipes.

Fabrication

GroovJoint manufactures a variety of stainless steel customer fabrications and specialty fittings designed to the customer’s needs.

Specialty products include (but are not limited to):

Grooved fittings are available in other alloys such as Titanium, AL6XN, and Hastalloy grades.

Capabilities include:

Header Construction

Job Site

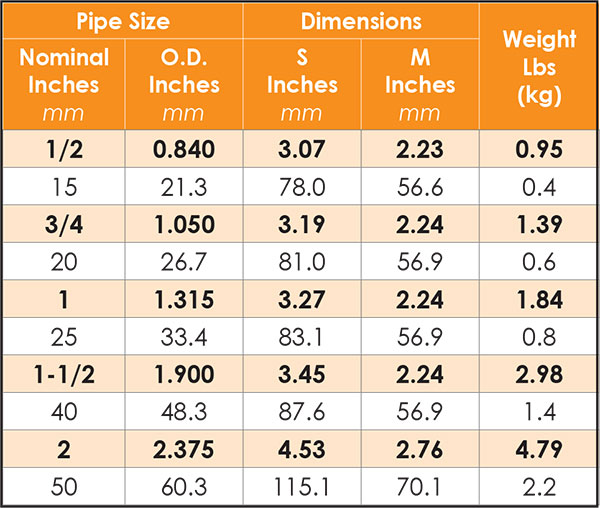

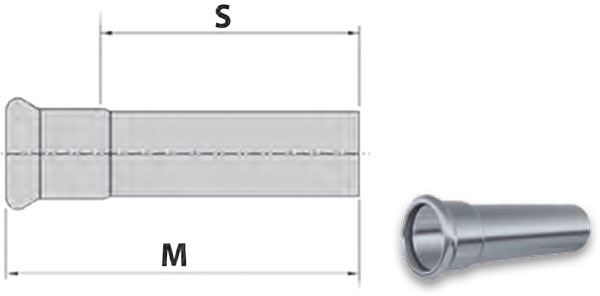

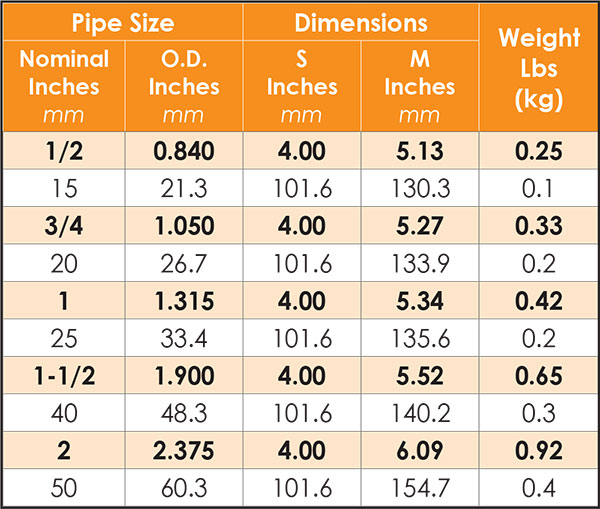

Stainless Steel Press Style Fittings

PressJoint Stainless Steel Press Style Fittings Product Line

We are presenting in this catalogue our range of Pressjoint products, the stainless steel tube and Pressfitting system which allows making facilities in a very easy way, without using welding or threads, saving a considerable amount of time and money.

These are the main applications of our system: compressed air, heating facilities, sanitation facilities, fire-extinguishing system (sprinkler), solar energy, plumbing, industrial facilities, shipping facilities and mining.

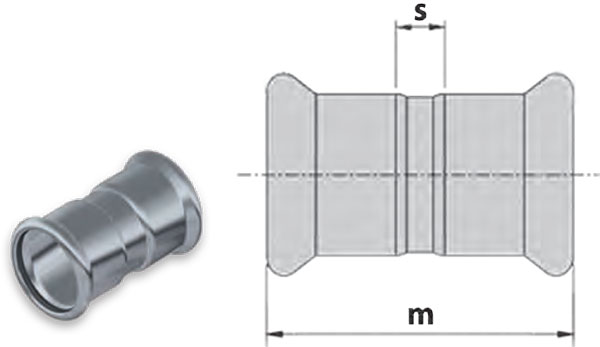

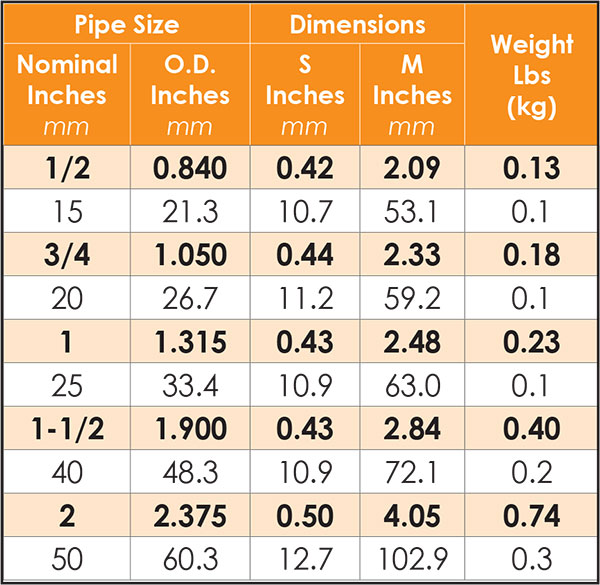

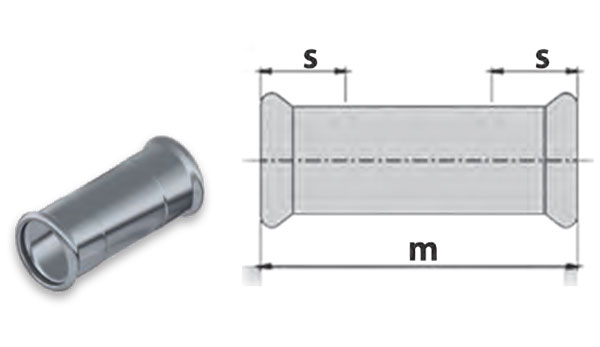

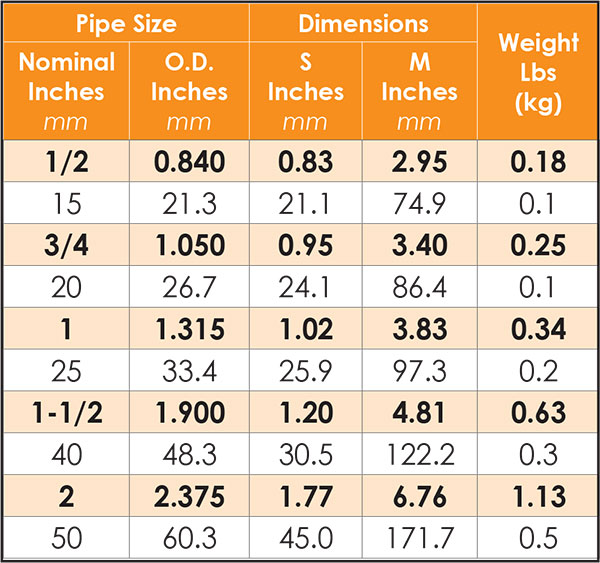

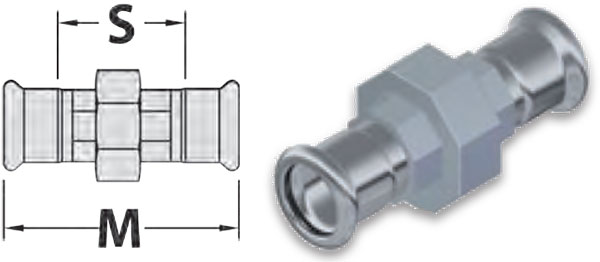

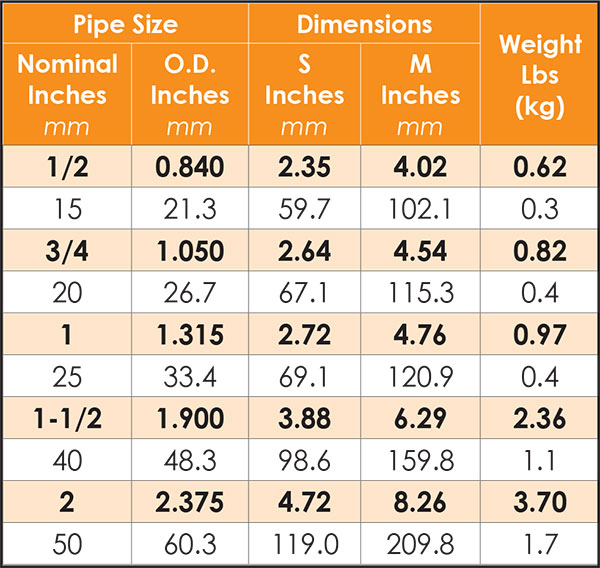

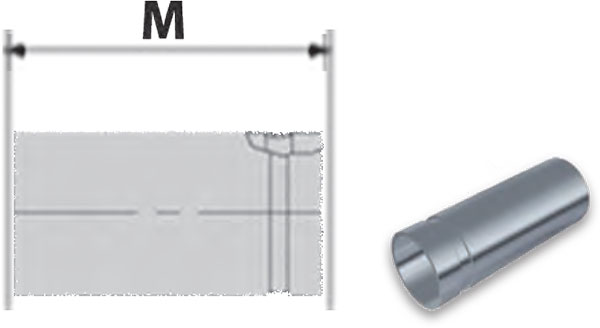

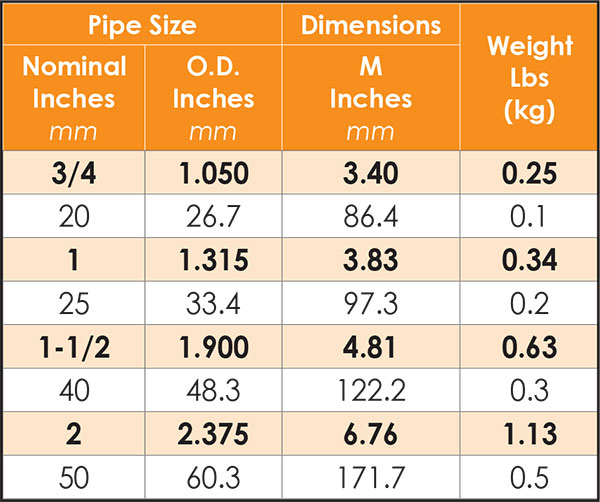

Couplings

Slip Couplings

316 SS 90º Elbows

316 SS 90º Street Elbows

316 SS 45º Elbows

316 SS 45º Street Elbows

316 SS Reducing Tee w/FPT Branch

316 SS Fitting by Press Reducer

316 SS Reducing Tees

316 SS Tees

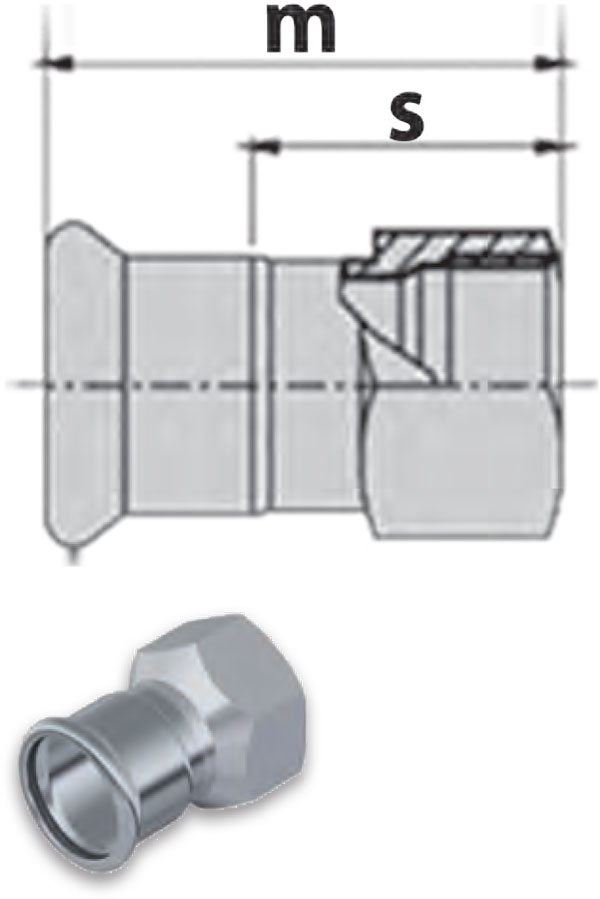

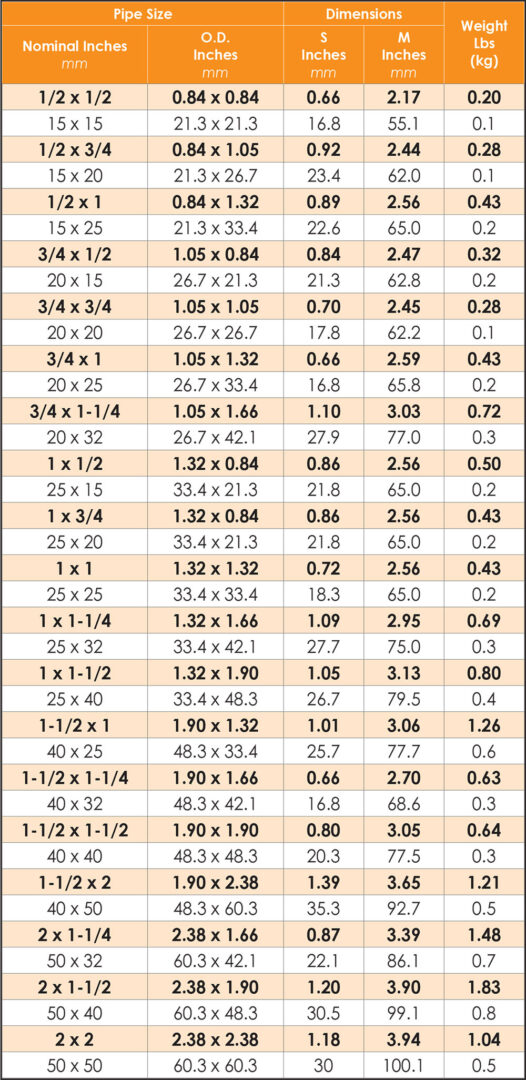

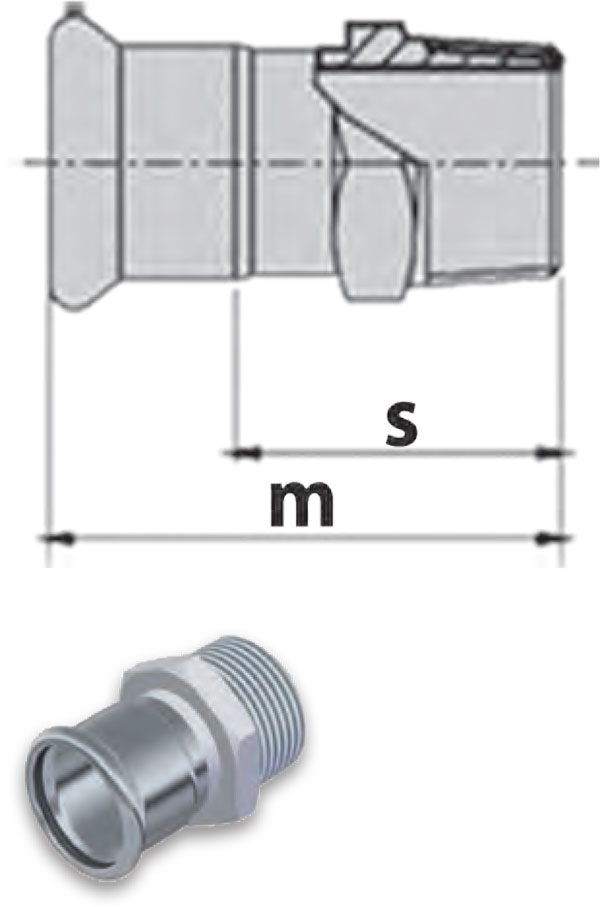

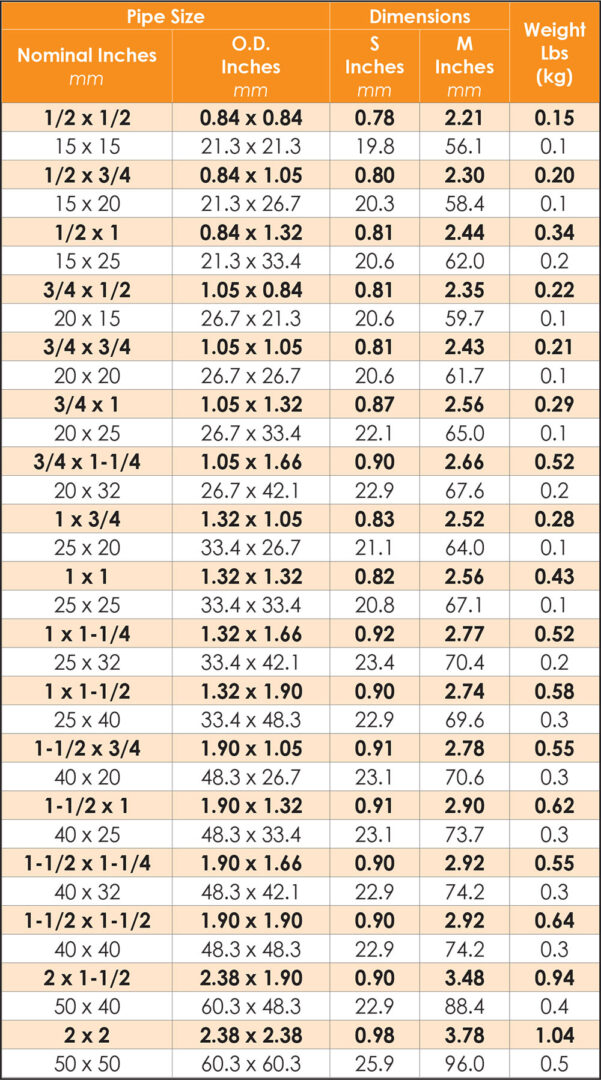

316 SS Female Adaptors

316 SS Male Adaptors

316 SS Flange Adaptors Press x Flg

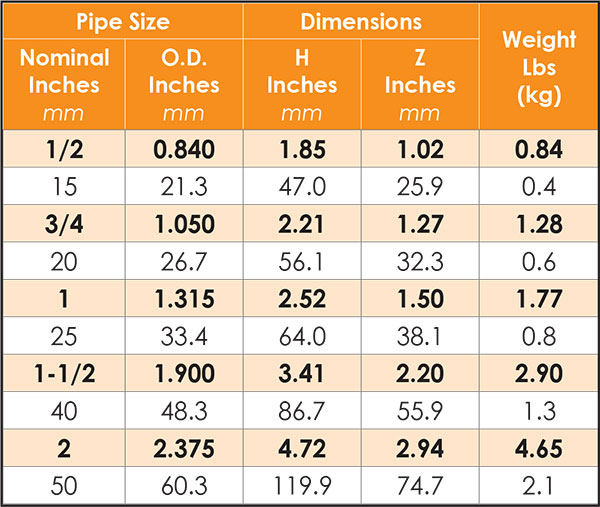

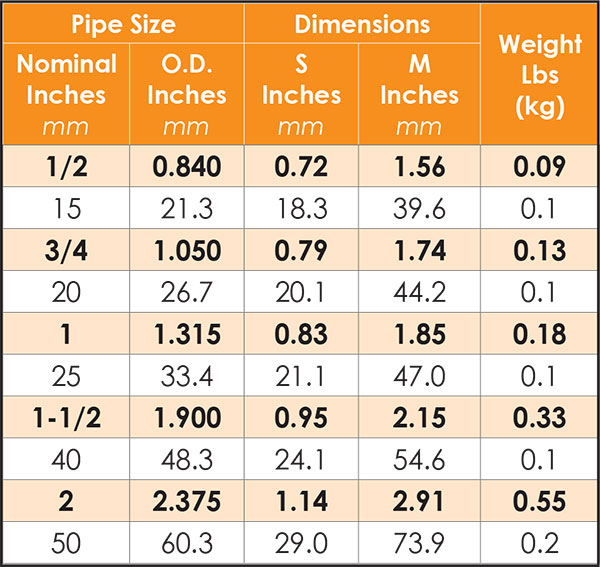

316 SS End Caps

316 SS Unions Press x Press

316 SS Transition Nipple

316 SS Van Stone Flg Adaptors

316 SS Weld Adaptors

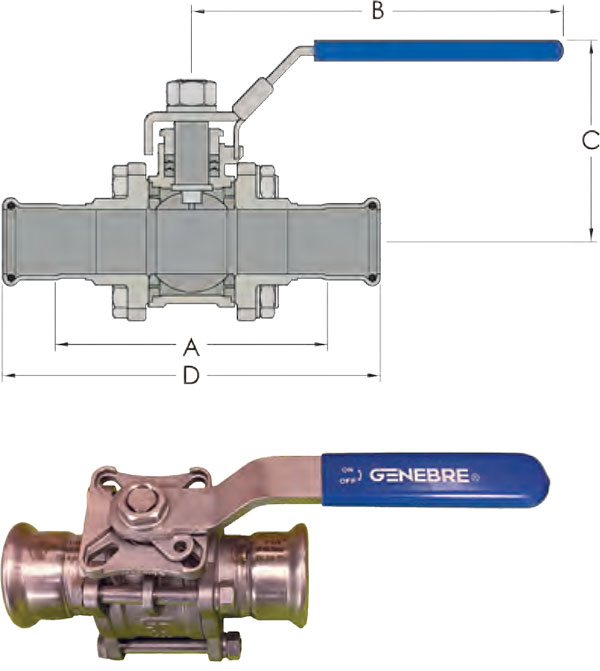

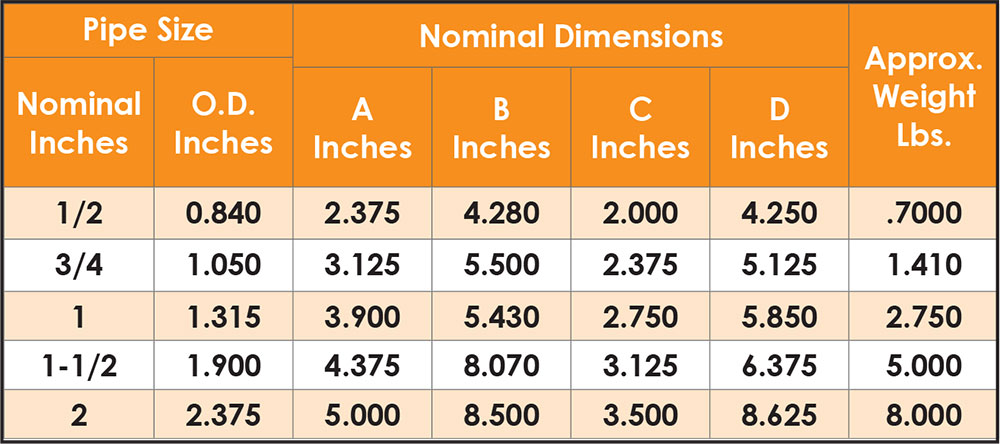

3 PCS SS Ball Valve Press x Presses

Actuation

Available upon request in either pneumatic or electric.

Press Fitting Recommendations

PressJoint Stainless Steel Fittings are a product line of press style joined press stainless steel fittings ranging in size from 1 ⁄ 2" – 2". This press style system can be used with both Sch. 5 and Sch. 10 Stainless Steel pipe. PressJoint fittings have a pressure rating maximum of 300psi (depending on media temperature) using the approved press tools.

TECHNICAL DATA

Approvals: PressJoint Stainless Steel Fittings are Certified to NSF/ANSI 61 by NSF.

Working Temperature: Depending on O-Ring Seal selection, temperatures range from -22ºF to 300ºF. Refer to the O-Ring Seals section in this data sheet for specific temperature ranges.

Threaded Connections: All threaded connections meet ANSI/ASME B 1.20.1 NPT.

Flange Connections: Flange connections are compatible with ANSI Class 125/150 bolt patterns.

MATERIAL SPECIFICATIONS

Fitting Housing: Stainless Steel per ANSI 316/316L with a wall thickness of 0.059˝(1.5mm) and the following characteristics:

- Hygienic, as demonstrated in the food, beverage, and pharmaceutical industries

- Less heat conduction than other materials

- The use of molybdenum results in excellent performance in chlorinated environments

Working Pressure: The working pressure range is from full vacuum to 300psi (20.7 bar) on Sch. 5 and Sch. 10 Stainless Steel Pipe.

O-Rings: O-Ring style gaskets are resistant to hot water, ageing, and additives commonly used in drinking water.

- EPDM O-Ring Seal – Black color – 4ºF to 230ºF (-20°C to 110°C). For cold and hot water, heating systems, oil-free compressed air systems and many chemical services. Excellent oxidation resistance. NOT FOR USE WITH HYDROCARBONS.

- Nitrile O-Ring Seal – Gray color, -13ºF to 230ºF (-25°C to 110°C). Petroleum products (except diesel). vegetable oils, mineral oils, and compressed air with oils. NOT FOR USE WITH HOT WATER OR HOT DRY AIR.

- FKM O-Ring Seal – Green color - 4ºF to 356ºF (-20°C to 180°C). Hydraulic fluids, Process Water, Chlorinated hydrocarbons and oxidizing acids. NOT FOR USE WITH Ammonia.

GENERAL NOTES – O-RINGS:

- Warning: Piping systems must always be depressurized and drained before attempting disassembly and or removal of any components.

- GroovJoint reserves the right to change specifications, designs and or standard without notice and without incurring any obligations.

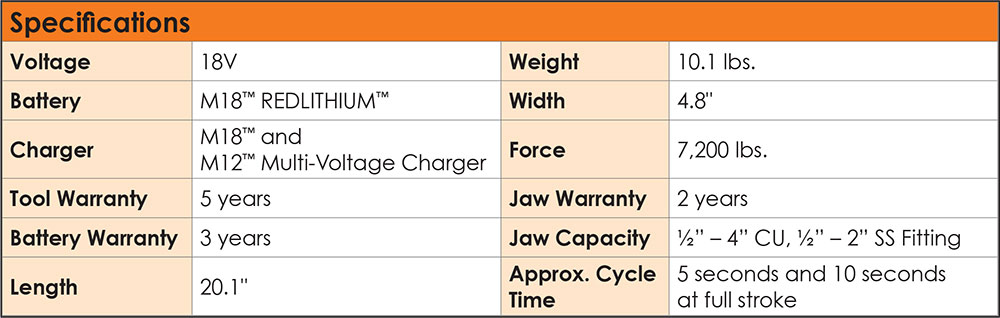

Pressfitting Tools

M18™ Force Logic Long Throw Press Tool 1/2"-1" Kit

Overview:

The M18™ Force Logic™ Long Throw Press Tool is the smallest, lightest press tool available today. It features an in-line design, offers the most ergonomic solution for navigating around installed pipes, and also delivers on the highest level of press accuracy and reliability available. The M18™ Force Logic™ Press Tool monitors the force output to ensure quality connections and features the best calibration standard in the industry.

Features:

Contents:

This tool is the only tool authorized by GroovJoint to be used with the GroovJoint press system.

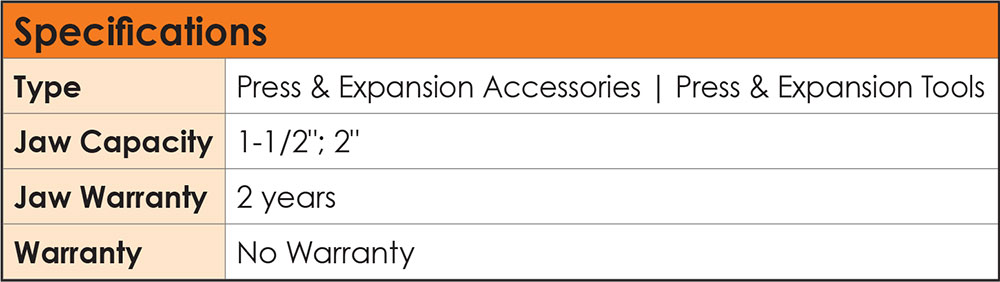

M18™ 1-1/2" & 2" SS Rings

M18™ Force Logic™ Stainless Steel Press Rings provide a solution that takes the advantage of press versus welding or threading to the max. Pressing 1-1/2 - 2" pipes using a 2-hinge design provides quality connections in close quarters. M18™ SS Press Rings require the Ring Jaw 2.

Features:

Ring Jaw 2

M18™ Force Logic™ Ring Jaw 2 provide a solution that takes the advantage of press versus welding or threading to the max. Pressing 1-1/2 - 2" pipes using a 2-hinge design provides quality connections in close quarters. M18™ Ring Jaw 2 is designed for use with the 1-1/2" and/or 2" M18™ SS Press Rings.

These accessories are authorized by GroovJoint to be used with the GroovJoint press system.

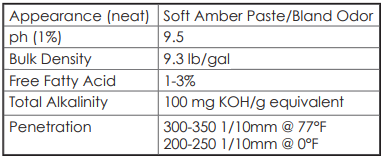

Coupling Gasket Grease

TUF-LUBE™ Grooved Coupling Gasket Grease

Tuf-Lube is a mixed fatty acid soap dispersed in glycols and water solvents with a clay pigment filler.

It resists evaporation and will not freeze.

Mating of abutting pipes forces the gel into the cavity, thus providing the needed lubrication to complete coupling and seal the joint.

The soap lubricant does not dry out when gaskets are stored in sealed plastic containers or bags.

The information contained herein is produced in good faith and is believed to be reliable but is for guidance only. GroovJoint cannot assume liability or responsibility for results obtained in the use of its product by persons whose methods are outside or beyond our control. It is the user's responsibility to determine the suitability of any of the products, methods of use, or preparation prior to use, mentioned in our literature. It is the user's responsibility to observe and adapt such precautions as may be advisable for the protection of personnel and property in the handling and use of any of our products.